As the demand for sustainable and recyclable materials grows across the packaging industry, food-grade rPET has emerged as a critical input for manufacturers. But navigating the regulatory landscape around food contact materials is no small task. In India, FSSAI-certified food-grade rPET resins are becoming a key requirement, especially for brands that want to stay compliant, transparent, and future-ready.

JB Ecotex Ltd. is proud to offer FSSAI-certified food-grade rPET resins to meet the growing needs of packaging manufacturers in India and beyond. In this blog, we want to give the complete information on what FSSAI compliance means, why it matters for the food packaging industry, and how our FDA and FSSAI-approved resins are designed to meet these expectations.

What is FSSAI Compliance in Food-Grade rPET?

The Food Safety and Standards Authority of India (FSSAI) is the national regulatory body responsible for food safety in the country. When it comes to food-contact packaging, FSSAI sets specific standards for material safety, migration limits, and contamination risk.

FSSAI-certified food-grade rPET resins are those that have passed extensive testing for suitability in direct contact with food and beverages. These tests typically assess residual contaminants, heavy metals, and migration of harmful substances into food. Only materials that meet the required safety and hygiene criteria are granted certification.

This certification ensures that the recycled resin being used has undergone proper decontamination and cleaning process, and that it will not pose a health hazard to the end consumer.

What Are the New Regulations on Recycled Content?

India’s Plastic Waste Management (Amendment) Rules are now driving a strong push toward incorporating recycled content in food-contact packaging. Under the latest mandates, manufacturers will be required to include a minimum percentage of recycled plastic in packaging materials, gradually increasing to stricter thresholds by 2025 and beyond.

This move aims to reduce dependency on virgin plastic and improve traceability across the packaging value chain. To comply, manufacturers must source materials that are not only recycled but also certified safe for direct food contact.

Sourcing FSSAI-certified food-grade rPET resins ensures readiness as these mandates tighten, helping avoid non-compliance risks and costly disruptions.

Why This Matters for Packaging Manufacturers

If you manufacture PET bottles, trays, preforms, or sheets for food and beverage brands, compliance is no longer optional. FSSAI compliance is becoming a baseline requirement for large-scale buyers, especially as India moves toward stricter regulations on the use of recycled content in food packaging.

With mandatory recycled content percentages set to increase, packaging manufacturers must now source certified rPET resins in India that can legally and safely be used in direct food contact applications.

Without FSSAI certification, packaging made with recycled materials may not pass audit or regulatory checks, putting both your clients and your operations at risk.

What is the Role of FDA Certification?

While FSSAI governs Indian standards, FDA certification refers to compliance with the U.S. Food and Drug Administration’s regulations for food-contact materials. For Indian manufacturers serving international clients or exporting food-grade products, FDA-approved resins provide an additional layer of assurance.

At JB Ecotex Ltd., we provide both FSSAI-certified food-grade rPET resins and FDA-approved options. This dual compliance ensures that our materials meet globally accepted standards for purity, traceability, and performance.

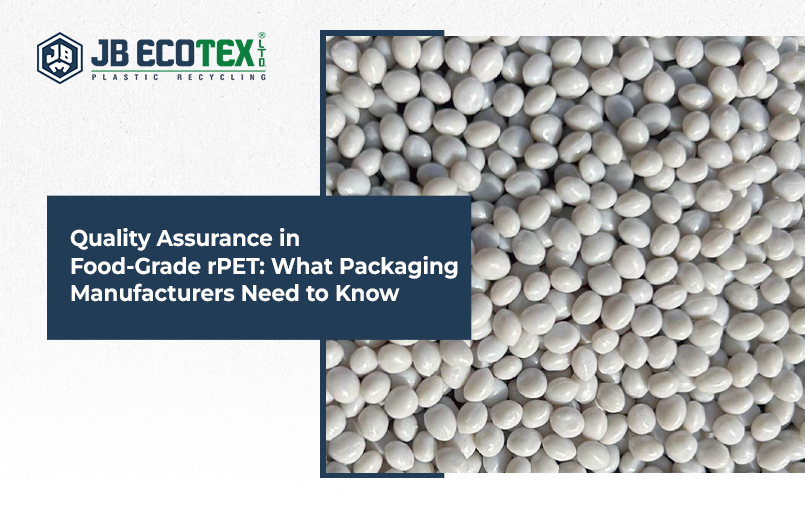

What Makes an rPET Resin Truly Food-Grade?

Not all recycled PET resins are suitable for food applications. A certified rPET resin in India must meet the following standards:

1. Thorough sorting and washing of input PET flakes

2. Use of advanced decontamination systems, such as vacuum extrusion

3. Batch testing for migration, residue, and heavy metal content

4. Documented traceability of source material

5.Certification from a recognized body (like FSSAI)

JB Ecotex uses a high-performance Erema Vacunite system for decontamination. Our closed-loop process ensures that the resin not only meets but maintains the required safety thresholds through each stage of production.

Specifications of JB Ecotex Food-Grade rPET Resins

Traceability in Food-Grade Resin Supply Chains

Traceability is now a necessity in food-grade packaging. Manufacturers need to ensure that every input material used in their packaging line can be traced back to its origin. At JB Ecotex, traceability is embedded into our process.

Each batch of FSSAI-certified food-grade rPET resin is logged with a digital record, including source details, decontamination protocol, test reports, and shipment validation. This level of documentation not only supports audit requirements but also builds confidence across the value chain.

With increasing focus on transparency and accountability in packaging, having traceable resin is a strategic advantage and a growing expectation among global food brands.

Our certified resins are designed to meet the functional and safety needs of modern food packaging operations. Key specifications include:

1. Intrinsic Viscosity (IV): Customizable to suit application needs

2. Colour Index: As per industry standard

3. Heavy Metal Residue: Below permissible migration limits

4. Contamination Control: Erema Vacunite technology enables deep decontamination

5. Documentation: Batch-level traceability, quality certifications, compliance declarations

These specifications help manufacturers meet both production and compliance requirements without compromising on performance.

Typical Applications of FSSAI Certified rPET

FSSAI-certified food-grade rPET resins are ideal for a range of food-contact packaging products, such as:

1. Water and beverage bottles

2. Preforms and blow-moulded containers

3. Food trays and rigid packaging

4. Thermoform applications

Each use case requires both functional reliability and regulatory clarity. JB Ecotex’s materials are engineered for consistency, tested across batches, and shipped with documentation support that makes audits easier.

What Manufacturers Should Be Vigilant About

Choosing the Right rPET Resin Supplier

With new regulatory pressure and growing consumer scrutiny, the resin supplier you choose can directly affect your brand’s compliance, efficiency, and trustworthiness. Here’s what to consider:

1. Can the supplier provide valid and current FSSAI and FDA certifications?

2. Do they support trial samples and product testing in your application?

3. Is there clear documentation and traceability for every batch?

4. Are they equipped with recognised decontamination technology like Erema Vacunite?

5. Do they understand EPR requirements and support your compliance strategy?

JB Ecotex works closely with manufacturers to ensure that these boxes are checked. From technical consultations to quality audits, we are a partner in more than name.

As is evident, choosing recycled resin has upgraded to more than just a cost or availability decision. Manufacturers need to watch for:

1. Proof of FSSAI certification, not just verbal assurance

2. Detailed documentation for every batch

3. Material performance in actual application conditions

4. Compatibility with intended food-contact use

5. Vendor’s process control and traceability systems

JB Ecotex helps clients review all of these checkpoints through pre-supply audits, sample validation, and direct support.

Common Questions Manufacturers Ask

1. Can I export food-grade packaging made with JB Ecotex resins?

Yes. With FDA and FSSAI certification in place, our resins support both domestic and international packaging applications.

2. Do I need documentation for each shipment?

Absolutely. We provide batch-wise quality reports, compliance declarations, and supporting traceability records with every dispatch.

3. Is there a difference between food-grade and industrial rPET?

Yes. Only food-grade rPET undergoes a certified decontamination process and passes safety migration tests. Industrial-grade resin is not approved for direct food contact.

4. How early should I switch to certified rPET?

With compliance deadlines approaching, switching now allows time for trials, onboarding, and process alignment.

5. Will this help with EPR compliance?

Yes. Sourcing certified rPET resins in India contributes to Extended Producer Responsibility (EPR) goals, especially when used in food-contact packaging.

How JB Ecotex Supports You

JB Ecotex provides more than material. We support your compliance journey with:

1. FDA and FSSAI certified food-grade rPET resins

2. Batch testing and traceability documentation

3. Technical guidance and sampling support

4. Aligned logistics and supply planning

Our focus is on clarity, safety, and service that helps you keep your operations audit-ready and production-ready.

The Road Ahead for FSSAI Compliant rPET in India’s Packaging Industry

India’s packaging ecosystem is moving toward a more transparent and circular model. For food-grade packaging manufacturers, sourcing the right resin is the first and most important step.

With FSSAI-certified food-grade rPET resins from JB Ecotex, you’re choosing a partner that is already aligned with the standards that matter.

Let’s build packaging that meets expectations and earns trust — from brand to shelf to consumer.

To learn more or request a technical consultation, reach out to our team at connect@jbecotex.com