you can say about fibre. It stretches, blends, insulates, bounces back. But in 2025, fibre does more than perform. It signals intent.

For textile manufacturers, choosing between Recycled Polyester Staple Fibre (RPSF) Over Virgin PSF is no longer just about price or availability. It’s about what the material says about your brand, your process, and your preparedness for where the textile industry is headed next.

At JB Ecotex, we’ve spent years working with recycled inputs, and we’ve seen how decision-making around materials is changing. So, if you’re wondering whether it’s time to rethink your sourcing, here are five reasons why more manufacturers are opting for Recycled Polyester Staple Fibre (RPSF) Over Virgin PSF.

1. Lower Environmental Footprint

The most obvious and urgent reason to choose Recycled Polyester Staple Fibre (RPSF) Over Virgin PSF is environmental. Virgin PSF relies on fossil-based raw materials, often processed through energy-intensive systems. RPSF, on the other hand, is made from post-consumer PET waste, reducing the need for raw resource extraction.

It’s not just a feel-good switch. Textile buyers, auditors, and even retail customers are tracking material origins and sustainability metrics more closely. Opting for recycled polyester staple fibre is a clear step toward aligning with modern procurement and ESG frameworks.

2. Supply Chain Stability

Global supply chains for virgin polymers have faced unpredictability in pricing, transport, and regulatory pressure. With increasing demand for alternative inputs, Polyester fiber manufacturers in India are actively investing in recycling infrastructure and sourcing partnerships that enable RPSF to be a reliable, scalable input.

Manufacturers working with RPSF vs virgin PSF consistently mention greater control over regional sourcing, less dependency on petrochemical volatility, and more room for innovation across blends.

3. Regulatory Readiness

Compliance expectations are no longer optional. India’s EPR (Extended Producer Responsibility) framework is already pushing for recycled content disclosures, and many international buyers are asking for traceability documents as a prerequisite.

By choosing Recycled Polyester Staple Fibre (RPSF) Over Virgin PSF, manufacturers set themselves up to respond faster to documentation needs, buyer queries, and audits. The narrative is already shifting. Recycled input is becoming the default starting point in many procurement conversations.

4. Buyer Alignment and Brand Value

From big export houses to niche domestic brands, the demand for recycled polyester staple fibre is now tied to storytelling. Fibre is no longer just a line item on a BOM sheet. It’s a symbol of how seriously a business takes its environmental impact.

Using RPSF enables manufacturers to meet buyer expectations around transparency and sourcing responsibility. It builds long-term trust. It communicates agility and forward-thinking to sourcing partners.

And when buyers compare RPSF vs virgin PSF, it’s not just about specs. It’s about alignment with the language their own customers want to hear.

5. Evolving Design and Blending Possibilities

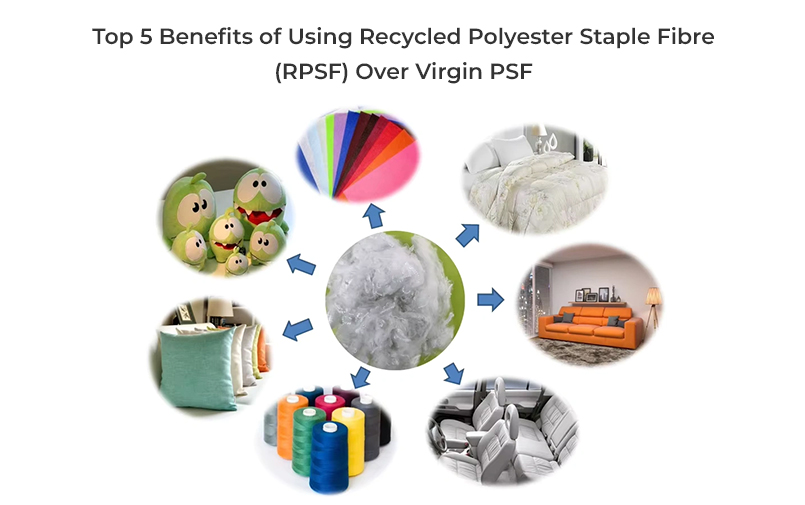

Many spinning units and converters we speak to are experimenting with new blends — cotton + RPSF, modal + RPSF, or technical mixes for automotive and industrial use.

The versatility of Recycled Polyester Staple Fibre (RPSF) Over Virgin PSF in blended applications allows for fabric innovation without losing strength, handle, or durability. The compatibility across use cases continues to improve as process consistency gets better.

Our Products, Our Process, and What You Should Know

At JB Ecotex, we produce RPSF using PET flakes processed in-house through carefully monitored washing, drying, and extrusion systems. Our offerings cover:

1. Hollow and solid fibre for stuffing and insulation

2. Fibres suitable for yarn spinning and blending

3. Custom grades developed for industrial and nonwoven use

We often get asked:

1. Are your fibres certified?

2. How do you manage batch consistency?

3. Can this work for our end-product quality needs?

We support stakeholders with product data, sample testing, and traceability documents. While we don’t make product claims, we work closely with partners to enable confident adoption and scaling.

Where RPSF Works Best

Every fibre has its moment. RPSF shines in:

1. Apparel basics and athleisure, where softness meets durability

2. Nonwovens and interlinings, where consistency matters more than appearance

3. Pillow and mattress fillings, where resilience, loft, and sustainability overlap

4. Home furnishings and upholstery blends, where feel and finish need to stay reliable

5. Automotive textiles, where regulations around recycled content are starting to surface

These applications have one thing in common: they demand performance and process flexibility without overlooking traceability. RPSF often fits that brief.

Our RPSF Range at a Glance

You can explore our full portfolio of RPSF products on our website:

🔗 https://jbecotex.com/recycled-polyester-staple-fibre/

Some highlights include:

1. Hollow Conjugated Siliconised RPSF

2. Solid RPSF for spun yarn

3. Black, white, and coloured variants across deniers

Whether you’re scaling up sustainable production or testing blends for a specific market, our team supports documentation, compliance queries, and tech specs to help you make informed decisions.

Global RPSF Insight: 2025 and the Shift to RPSF

A recent Textile Exchange study forecasts that by 2025, global brands will aim for 45% recycled polyester use. This momentum supports greater investment in traceability, fibre quality, and recycled supply chain accountability.

FAQs

1. What is the main difference when comparing RPSF vs virgin PSF?

Virgin PSF is made from petroleum-based feedstocks, while RPSF is derived from recycled PET bottles. The two materials may perform similarly depending on application, but differ in origin and environmental profile.

2. Can RPSF match virgin PSF in durability?

For many uses, yes. Blending trials and sample evaluations are the best way to assess match with your specific product needs.

3. Are there incentives for using RPSF?

In some regions, yes. Additionally, buyers are more frequently requesting recycled content, which may affect long-term vendor selection.

4. How can we trial JB Ecotex RPSF?

Reach out to our technical team via connect@jbecotex.com. We’ll coordinate samples, specifications, and next steps.

JB Ecotex Perspective

Fibre choices aren’t small decisions. They shape product outcomes, cost structures, and brand positioning. In 2025, choosing Recycled Polyester Staple Fibre (RPSF) Over Virgin PSF sends a clear message: we are building forward.

JB Ecotex supports manufacturers ready to explore that shift. And we do it with attention, data, and consistency.