Recycling PET is one thing. Producing mechanical B2B rPET resins pure enough for high-performance use? That’s where the real challenge lies. Even the smallest contaminants can compromise the quality, making the material unsuitable for food-grade packaging or durable textiles. Plastic recycling contamination isn’t always noticeable but it can significantly affect the integrity and performance of recycled materials, especially in demanding applications.

At JB Ecotex, we’ve seen this problem firsthand—and solved it with precision. Our fully automated recycling process leaves no room for error. Every stage, from sorting to final production, is designed to detect and remove impurities. We use advanced technologies to identify contaminants in recycled PET, eliminating them long before they can compromise the final product. The result? Consistently clean, high-quality rPET resins you can count on, batch after batch.

The Contamination Challenge in Plastic Recycling

Contaminants in recycled PET aren’t just a hindrance to production. It’s more specific than that. They’re a barrier to achieving the quality manufacturers need. Common culprits include:

- Non-PET Plastics: PVC, PP, or PE that sneak into recycling streams.

- Adhesives and Labels: Residual glue from bottle labels that can degrade PET.

- Dirt and Debris: Micro-particles that escape initial cleaning processes.

- Metals: Tiny fragments from bottle caps or other sources.

These contaminants affect the appearance and greatly impact the performance of rPET.

For example:

- PVC contamination can cause yellowing and weaken the material.

- Adhesives can clog machinery and create defects in the final product.

- Metals can damage extruders and other equipment.

For manufacturers relying on the exceptional characteristics of premium mechanically recycled food-grade granuals, even minor contamination can mean the difference between a flawless production run and costly downtime.

How Contamination Impacts rPET Quality

The presence of contaminants doesn’t just affect the recycling process. The fact of the matter is that it has a ripple effect on the entire supply chain. That is not an exaggeration. These are the common issues that may arise:

- Production Delays: Contaminants can clog machinery, forcing unplanned stoppages.

- Quality Issues: Impurities can lead to defects like haze in packaging or weak spots in fibres.

- Increased Costs: Rejected batches and rework add unnecessary expenses.

- Regulatory Risks: For food-grade applications, contamination can mean failing safety standards.

We don’t have to tell you that the stakes are high. That’s why eliminating contamination is the foundation of everything we do. We understand how crucial it is to get it right.

Our Fully Automated Solution: Precision Without Compromise

At JB Ecotex, we’ve built a 100% automated recycling process that leaves no room for error. Here’s how we tackle contamination at every stage:

1. Advanced Sorting: The First Line of Defense

Contamination control starts with sorting. Our fully automated system uses:

- Near-Infrared (NIR) Technology: To identify and separate PET from non-PET materials like PVC or PP.

- Optical Scanners: To detect and remove coloured PET that doesn’t meet specifications.

- Metal Detectors: To catch even the smallest metal fragments.

Why It Matters: Clean input means fewer headaches downstream.

2. Deep Cleaning: Removing What Others Miss

Labels, adhesives, and dirt are more than surface-level problems. Our automated cleaning process includes:

- Enzyme-Based Pre-Washing: Breaks down adhesives without damaging PET.

- High-Pressure Rinsing: Removes dirt and debris from every nook and cranny.

- Friction Scrubbing: Dislodges embedded contaminants without degrading the material.

Why It Matters: Residual glue can yellow clear PET. We eliminate it, so you don’t have to.

3. Precision Grinding: Consistency is Key

Uniform flakes are essential for smooth processing. Our automated grinders:

- Produce flakes of consistent size and thickness.

- Remove dust and micro-particles that can cause defects.

Why It Matters: Flakes that melt evenly mean fewer machine jams and better end products.

4. Multi-Stage Washing: Purity at Every Step

Our automated washing system includes:

- Hot Water Baths: To dissolve any remaining contaminants.

- Chemical Washing (When Needed): To target stubborn residues.

- Advanced Filtration: To remove micro-contaminants.

Why It Matters: Clean flakes mean fewer rejects and higher yields.

5. Rigorous Quality Control: Automated Testing for Perfection

Every batch of rPET undergoes automated testing to ensure it meets the highest standards:

- IV Testing: To confirm viscosity levels align with your specifications.

- Contamination Scans: Using spectroscopy to detect even trace impurities.

- Moisture Analysis: To ensure flakes are dried to optimal levels.

Why It Matters: Automated testing eliminates human error, delivering consistent results every time.

Why Automation Makes the Difference

In a world where precision is non-negotiable, automation is the key to consistency. Our fully automated process ensures:

- Zero Human Error: Every step is controlled by advanced systems, eliminating variability.

- Real-Time Monitoring: Sensors track every stage, flagging issues before they become problems.

- Scalability: Automated systems handle large volumes without compromising quality.

For manufacturers, this means mechanically recycled food-grade granules you can trust. Batch after batch is uncompromised in its quality.

To make all of the above possible, we use some of the most efficient technologies available in our industry, many of which are rare in India. Here’s a look at what powers our process:

- Boretech Food-Grade Washing Line: Our advanced washing line ensures waste PET bottles are processed according to strict food-grade guidelines. Equipped with the latest sorting systems and the Zerma Crusher, it delivers the purest quality rPET flakes required for food-grade granules.

- EREMA VACUREMA Technology: We have installed the vacuum-supported solid-state polycondensation (SSP) system from Polymetrix. It ensures the safe extrusion and decontamination of rPET flakes, meeting USFDA food-grade standards.

These technologies work together to make our process smooth, efficient, and reliable, ensuring we deliver top-quality products every time.

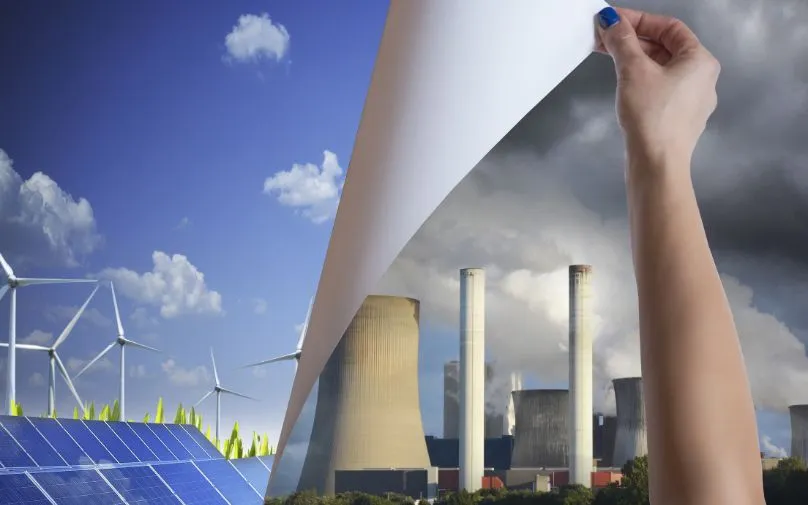

Applications of High-Quality rPET Resins

Our contamination-free rPET resins are trusted by manufacturers across industries:

- Food-Grade Packaging: Safe, clear containers and bottles that meet stringent purity standards.

- Textiles: Strong, durable fibres for clothing, carpets, and industrial fabrics.

- Automotive: High-performance components that meet rigorous quality requirements.

- Industrial: Strapping bands, sheets, and films that deliver consistent results.

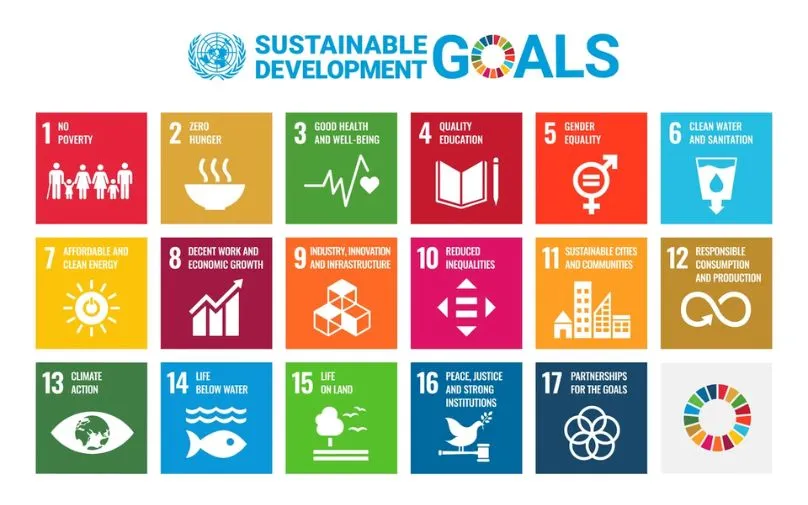

Let’s Build a Cleaner Future Together

Contamination in recycled PET isn’t a problem we have to accept and learn to live with anymore. With the right processes and technology, producing mechanically recycled B2B rPET resins that meet the standards of quality and performance. We should know, it’s what we do every day at JB Ecotex.

But your trust isn’t something we ask for blindly. It’s something we’ve earned, and our certifications prove it:

- FDA Compliance: Ensures our rPET resins are safe for food-grade applications in the U.S., meeting the strictest purity standards.

- ISO 9001:2015: Our promise of consistent quality, backed by a system that leaves no room for error.

- ISO 14001:2015: Reflects our commitment to sustainability, ensuring our processes are as eco-friendly as the materials we produce.

These certifications aren’t just framed badges of honour on our wall. They’re proof of the systems, processes, and standards we’ve built to ensure every batch of rPET we deliver is as reliable as the last. We wouldn’t have earned them if we didn’t back up our promises with results. At JB Ecotex Ltd., we do everything it takes to make sure that we are never misaligned with our core values.

And that is why, when you choose JB Ecotex you choose raw materials that let you focus on what you do best—creating exceptional products. Because when your raw materials are flawless, so is your production.

Ready to Experience Contamination-Free rPET in India?

Contact us today to learn more about our fully automated recycling process and how we can help you achieve your sustainability and quality goals.