The beauty of nature is showcased by the earth’s lush forests, pristine waters, and vast oceans. However, human actions have marred this stunning scenery, leaving behind scars such as plastic pollution that taints even the most secluded corners of our world. At JB Ecotex Ltd., we place our faith in human creativity to revive and safeguard this natural magnificence.

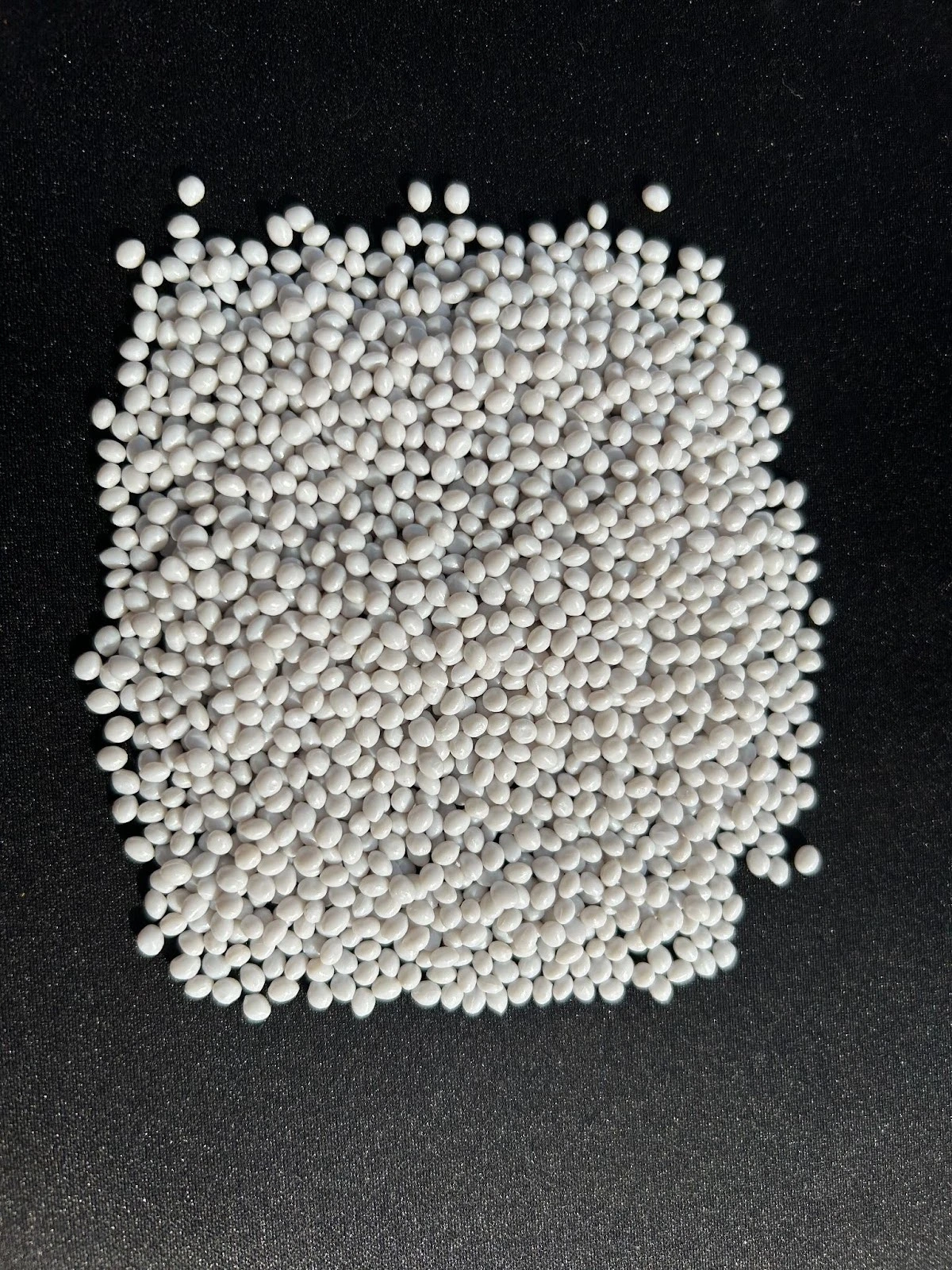

Through the collection of plastic waste from oceans, rivers, and urban areas, we convert it into high-quality rPET resins ideal for eco-friendly packaging solutions. Our cutting-edge recycling techniques and unwavering dedication to environmental conservation highlight our ability to utilize our skills in healing the planet. This ensures that upcoming generations can continue to be awestruck by the Earth’s wonders for years to come.

Understanding rPET: A Step Towards True Circularity

Recycled PET, or rPET, represents a significant stride towards achieving true circularity in the packaging industry. By converting used PET bottles into high-quality resins, we can continually reuse plastic, drastically reducing waste. This closed-loop system ensures that the same material can be repeatedly transformed into new bottles and packaging, thereby minimizing environmental impact.

Environmental Impact: Reducing the Carbon Footprint

The production of rPET resins consumes considerably less energy than the creation of virgin PET. According to research, the carbon footprint of rPET is up to 79% lower than that of virgin PET. This reduction is due to the decreased energy requirements and lower greenhouse gas emissions associated with the recycling process. At JB Ecotex Ltd., we leverage Erema VACUREMA technology to enhance the efficiency of our recycling operations, further minimizing environmental impact.

Ensuring Health and Safety: Meeting Global Standards

A critical concern for food and beverage manufacturers is the safety of their packaging materials. Advances in recycling technology have ensured that rPET resins are as safe as virgin PET for food-grade applications. JB Ecotex Ltd.’s rPET resins comply with stringent health and safety standards set by the European Food Safety Authority (EFSA), the US Food and Drug Administration (FDA), and the Food Safety and Standards Authority of India (FSSAI). This makes our rPET resins a reliable choice for manufacturers seeking sustainable yet safe packaging solutions.

Real-World Applications: rPET in Food and Beverage Packaging

1. Beverage Bottles

Leading beverage companies are increasingly adopting rPET for their bottles. For instance, PepsiCo had committed to using 100% recycled plastic in its beverage bottles across nine European markets by 2022. This shift not only reduces plastic waste but also meets consumer demand for more sustainable products.

2. Ready-to-Eat Meals

Ready-to-eat meal providers are exploring rPET for their packaging needs. By using rPET trays and containers, these companies can offer convenience without compromising on sustainability. This approach appeals to environmentally conscious consumers who prefer eco-friendly packaging options.

3. Food Containers

The dairy industry is also witnessing a significant uptake of rPET. Companies like Danone have started using rPET in their yoghurt containers, ensuring that the packaging is both sustainable and safe for food storage. This transition helps reduce the environmental footprint of food packaging while maintaining product integrity.

Policy Support: Facilitating Adoption

European Union Initiatives

Government regulations are playing a crucial role in promoting the adoption of rPET. The European Union, for example, mandates that all PET bottles must contain at least 25% recycled plastic by 2025. Similar policies are being implemented in other regions, encouraging manufacturers to incorporate rPET into their packaging. JB Ecotex Ltd. is well-equipped to meet these regulatory requirements, providing high-quality rPET resins that comply with international standards.

Indian Government Policies

In India, the government has been actively promoting recycling and the use of recycled materials. The Plastic Waste Management Rules, 2016, and its subsequent amendments mandate the use of recycled plastics and promote extended producer responsibility (EPR). These regulations encourage manufacturers to adopt sustainable practices, including the use of rPET, to manage plastic waste effectively. JB Ecotex Ltd. aligns with these policies, ensuring that our operations contribute to the national agenda of reducing plastic pollution.

Increasing Public Awareness: Driving Demand

Consumer awareness about the environmental benefits of rPET is growing, driving demand for products made from recycled materials. Educational campaigns and sustainability initiatives are crucial in changing consumer perceptions and encouraging the adoption of rPET. By highlighting the advantages of rPET, JB Ecotex Ltd. is actively contributing to this awareness, promoting a shift towards more sustainable packaging solutions.

Leading by Example: Case Studies of rPET Adoption

Nestlé Waters

Nestlé Waters has committed to using 50% recycled plastic in its bottles by 2025. This initiative highlights the company’s dedication to sustainability and sets a precedent for other manufacturers.

Unilever

Unilever aims to halve its use of virgin plastic by 2025, in part by increasing its use of rPET in packaging. This goal reflects the company’s broader commitment to reducing its environmental impact and promoting circular economy principles.

Join the Movement: Partner with JB Ecotex Ltd.

The shift towards rPET is not just a trend but a necessity for sustainable development. By partnering with JB Ecotex Ltd., manufacturers can access premium quality rPET resins that meet the highest standards of safety and sustainability. Our commitment to innovation and excellence ensures that our clients can confidently transition to more eco-friendly packaging solutions.

Let’s work together to create a sustainable future. Visit www.jbecotex.com to learn more about how JB Ecotex Ltd. can support your journey towards sustainability. Make the switch to rPET today and lead the way in sustainable packaging.