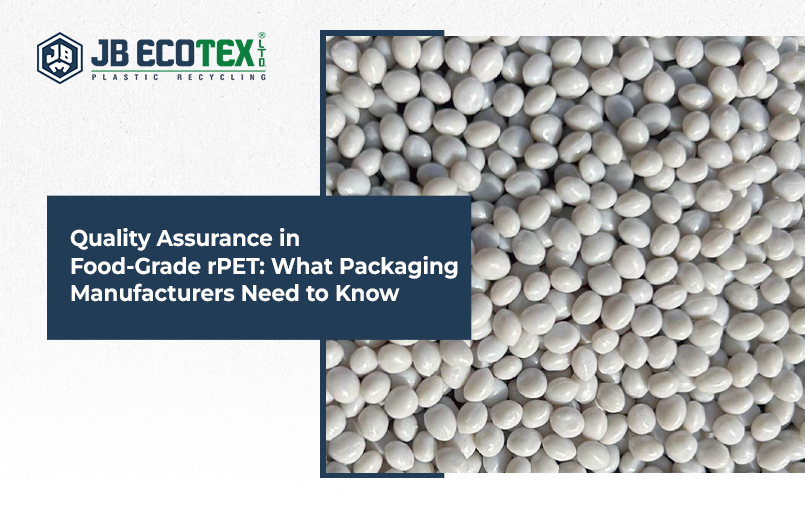

We Understand the Concerns About rPET in Food Packaging

For manufacturers in food packaging, switching to rPET granules goes beyond the government mandate to promote sustainability. For them, it is about safety, quality, and trust.

We know what you are thinking.

1. Can rPET really be as safe as virgin PET for food contact?

2. What do FDA and EFSA approvals actually mean?

3. How do I ensure my packaging meets compliance standards in different countries?

4. If I make the switch, will my customers trust my packaging?

These are real concerns. And if you have them, it means you are taking this responsibility seriously. And that is exactly what matters when it comes to food packaging.

At JB ECOTEX, we have spent years working in rPET production. And as one of the pioneers of mechanical food-grade rPET granules, we’ve also had the front-row seats to the doubts surrounding the credibility and safety of B2B rPET resins and simultaneously addressing these same questions with businesses like yours. We have seen the confusion, the misconceptions, and the frustration with unclear regulations.

Through this blog, we hope to break it down for you. We hope to help make sense of what FDA and EFSA regulations really mean for manufacturers, what FSSAI allows in India, and what you need to know before trusting an rPET granules supplier with your food packaging.

What Do FDA and EFSA Really Mean for Food-Grade rPET?

Regulatory agencies such as the FDA (Food and Drug Administration) in the U.S. and EFSA (European Food Safety Authority) in the EU set the highest global standards for food safety. If an rPET granules supplier claims to offer food-grade rPET, their product must comply with the stringent requirements set by these agencies. If rPET does not meet their standards, it is not safe for food contact.

For food packaging manufacturers, this is the single most important factor—because when food safety is questioned, so is your brand’s reputation.

FDA: What It Takes to Be Approved for Food Packaging in the U.S.

The FDA (Food and Drug Administration) sets some of the strictest safety standards in the world. If you are manufacturing food-contact rPET packaging in the U.S., compliance is essential.

To meet rPET granules FDA standards, here is what must happen:

1. The rPET must only come from post-consumer PET bottles originally used for food. This means no industrial waste, no non-food plastics—only bottles that were once used for drinks or food packaging.

2. The recycling process must completely remove all possible contaminants. This is critical. Not all rPET is the same. If it does not go through a proper decontamination process, it cannot be considered food-safe.

3. The final rPET granules must pass migration testing. This ensures that no harmful substances transfer to food when it is stored in rPET-based packaging.

The FDA does not approve products, only recycling processes. That means your rPET granules supplier must use an FDA-reviewed method to guarantee food safety.

🔗 Read more on FDA regulations for recycled plastics

EFSA: Europe’s Tough Standards for Food-Safe rPET

For food packaging manufacturers exporting to Europe, EFSA (European Food Safety Authority) regulations are non-negotiable.

Unlike the FDA, EFSA does not just look at final rPET granules, they evaluate the entire recycling process.

For rPET granules EFSA compliance, a supplier must:

1. Use only food-contact PET as the input material. Anything else is rejected.

2. Prove that their decontamination process eliminates all chemical residues.

3. Ensure that their final rPET granules are chemically identical to virgin PET.

If your supplier cannot prove this level of compliance, their rPET granules cannot legally be used for food packaging in Europe.

🔗 Read EFSA’s official guidelines on food-contact rPET

What This Means for Food Packaging Manufacturers

Let’s be honest. The real challenge for manufacturers is not just understanding the regulations—it is finding a supplier they can trust.

If your rPET granules supplier does not meet FDA or EFSA standards, here is what happens:

1. Your packaging may be banned in key markets like the U.S. and EU.

2. You risk product recalls if the rPET is found to be unsafe.

3. Consumers may lose trust in your brand if packaging safety is questioned.

So how do you avoid these risks?

1. Ask for full documentation. Your supplier should be able to show proof of compliance.

2. Ensure they follow an FDA and EFSA-approved recycling process. Not all rPET suppliers do.

3. Check their traceability reports. The source of their PET matters.

At JB ECOTEX, we make sure every batch of rPET granules meets global food safety standards. We work directly with manufacturers to ensure full traceability, compliance, and peace of mind.

Intrinsic Viscosity (IV): Why It Matters for rPET in Food Packaging

Here is something that many manufacturers overlook: Intrinsic Viscosity (IV).

This is what determines how strong, durable, and stable the rPET is.

1. rPET Granules 0.8 IV – Suitable for general food packaging, offering flexibility and reliability.

2. rPET Granules 0.84 IV – Designed for high-performance packaging that needs extra durability.

Choosing the right IV level ensures that your packaging maintains its integrity under different storage conditions.

What USFDA Certification Means for JB ECOTEX and Our Customers

For us at JB ECOTEX, holding USFDA certification is a clear validation of the meticulous care we put into producing high-quality, food-safe rPET granules.

What This Means for Our rPET Granules

1. Fully traceable and compliant with international food safety standards

2. Manufactured through an USFDA-reviewed recycling process

3. Guaranteed to meet migration testing for food-contact safety

What This Means for Our Customers

1. Zero uncertainty about compliance in U.S. markets

2. Reliable supply chain for safe, food-grade rPET

3. Strong documentation for traceability and regulatory approvals

Erema VACUNITE Technology: How We Ensure Maximum Purity in rPET

At JB ECOTEX, we work to continuously remain on top of compliance and in sync with the technological advancements in the industry. Our Erema VACUNITE technology is one of the most advanced PET recycling systems in the world, combining vacuum-assisted solid-state polymerization with nitrogen processing.

Why does this matter for food packaging manufacturers?

1. Removes all contaminants to meet the highest purity standards

2. Preserves the intrinsic viscosity (IV) of rPET granules

3. Reduces thermal degradation, improving rPET performance in packaging applications

4. Ensures USFDA food-contact safety compliance

The result is rPET granules that perform just like virgin PET while meeting the strictest global food safety regulations.

FSSAI: What Are the Food-Safe rPET Regulations in India?

For years, India’s FSSAI (Food Safety and Standards Authority of India) did not allow any recycled plastic in food packaging. The fear was contamination.

But as recycling technology advanced, FSSAI revised its guidelines.

For rPET to be legally used in food packaging in India, it must:

1. Be sourced from post-consumer PET bottles used for food.

2. Pass stringent decontamination and safety tests.

3. Match virgin PET in safety, purity, and migration performance.

This is a major milestone for the Indian packaging industry, but it also means manufacturers must be careful when choosing an rPET granules supplier.

🔗 Read FSSAI’s official food packaging regulations

Making the Transition to Safe, Sustainable rPET Packaging

Switching to rPET granules for food packaging is not just about meeting regulations. It is about:

- Keeping your products safe.

- Ensuring compliance across global markets.

- Providing customers with packaging they can trust.

At JB ECOTEX, we have worked with manufacturers across industries to provide USFDA-certified rPET granules that meet the highest safety standards.

If you are considering making the switch, here is what we recommend:

1. Verify your supplier’s compliance with global food safety regulations.

2. Ensure their rPET has the correct IV for packaging strength and durability.

3. Ask for full documentation to avoid regulatory risks.

The future of food packaging is sustainable, but it must also be safe.

There is no room for uncertainty when it comes to food-contact rPET granules. The risks are too high.

If you are a manufacturer using rPET for food packaging, the right supplier makes all the difference.

At JB ECOTEX, we help businesses make the switch to safe, sustainable, and compliant rPET packaging—without the guesswork.

If you are ready to move forward, let’s talk.