Hidden in Plain Sight: PET Flakes and Their Expanding Role in Manufacturing [2025 Update]

![Hidden in Plain Sight: PET Flakes and Their Expanding Role in Manufacturing [2025 Update]](/_next/image?url=https%3A%2F%2Fsetup.infiniqemarketing.online%2Fuploads%2F2569ea34-f867-4c31-b71a-e87403eab196%2Fblog%2F1762436358194_Banner.jpg&w=3840&q=75)

When a consumer picks up a soft-drink bottle or a salad tray, they rarely think about its origin. On the surface, these items look ordinary. Yet hidden inside each one is a silent enabler of modern manufacturing: PET flakes, created from used PET bottles, are steadily reshaping how industries respond to consumer expectations.

Shoppers today want packaging that reflects responsibility. They look for cues like “made from recycled content” or “supports circular economy.” Manufacturers meet these expectations not through last-minute marketing but by rethinking raw materials at the source. That is where PET flakes step in.

These small, uniform fragments form the feedstock for packaging resins, fibers, and films. Their journey from discarded bottles to renewed material tells a story consumers want to hear: a story of waste turned into value, invisibly woven into everyday products.

As industries race to balance compliance with consumer trust, PET flakes act as the bridge. They don’t carry a logo, a brand, or consumer recognition. Still, without them, many of the food-grade bottles, films, fibers, and sheets we use daily would not exist. They help packaging companies fulfill regulations while providing brands the opportunity to communicate sustainability authentically. Silent to the consumer eye, yet vital in shaping perception, PET flakes are redefining what it means for packaging to be both functional and responsible.

What Exactly Are PET Flakes?

PET flakes are the result of recycling post-consumer PET bottles. Collected bottles undergo sorting, label removal, cleaning, and hot washing before being cut into small, uniform flakes. These flakes then serve as raw material for resins, fibers, strapping, and films across industries.

At JB Ecotex, flakes are prepared with strict attention to parameters that matter for manufacturers:

- Flake Size: 2–12 mm for compatibility with extrusion processes.

- Bulk Density: ~300 kg/m³ for ease of storage and transport.

- Moisture Content: Less than 1%, critical to avoid processing issues.

- PVC Content: Kept below 35 ppm to prevent contamination.

- Metal Content: Less than 5 ppm for safe downstream processing.

These specifications are not just numbers. They define how well flakes will perform once they enter the machines of resin producers, textile spinners, or packaging converters.

Why Manufacturers Depend on PET Flakes

Virgin PET once dominated the plastics industry. But today, regulations, sustainability commitments, and consumer awareness have transformed recycled PET bottle flakes into an essential input.

For manufacturers, PET flakes offer:

- Compliance-readiness with food-contact and EPR rules.

- Process compatibility across textile, resin, and packaging machinery

- Consistency that reduces risk during high-volume production.

- Circularity benefits that align with consumer and regulatory expectations.

Every PET bottle flakes buyer is looking for stability, traceability, and reliability. PET flakes provide that foundation.

The Global Market Context

The use of PET flakes is not an isolated trend. It reflects a larger shift in how industries approach plastics.

- Global rPET demand is projected to grow at 9.7% CAGR through 2034, with food and beverage packaging leading the surge.

- Europe mandates at least 25% recycled content in PET bottles by 2025, with more ambitious goals for 2030.

- India’s Plastic Waste Management Rules under Extended Producer Responsibility require brands to integrate recycled materials into their packaging streams.

This rising demand places pet flakes manufacturers in India in a pivotal position. India’s scale in collection and recycling enables it to be a partner for global supply chains seeking rPET integration.

Technical Parameters Explained

For many buyers, the specifications of PET flakes directly determine success. Let’s look at why:

- Moisture (<1%) → High moisture leads to hydrolysis in extrusion, weakening resin or yarn strength.

- PVC (<35 ppm) → Even small amounts of PVC contamination can yellow bottles or compromise food safety.

- Metal Content (<5 ppm) → Essential to prevent machinery wear and product defects.

- Flake Size (2–12 mm) → Ensures uniform melting and extrusion, reducing production stoppages.

These parameters explain why PET flakes buyers don’t just ask for “flakes.” They ask for verified, tested flakes with reliable documentation.

Industry-Wise Applications of PET Flakes

1. Food and Beverage Packaging

Clear hot-washed PET flakes are converted into resins for:

- Bottle-to-bottle recycling.

- Food trays, films, and rigid containers.

- Dairy, beverage, and ready-meal packaging.

Packaging companies prefer clear flakes with low PVC levels, as safety and transparency are critical for consumer trust.

2. Textiles and Apparel

One of the largest uses of recycled PET bottle flakes is in textiles. Flakes are processed into polyester staple fiber (rPSF) and filament yarn.

Applications include:

- Apparel and sportswear.

- Upholstery and furnishings.

- Technical textiles like nonwovens.

For spinners, the consistency of flakes directly impacts fiber quality. That is why pet flakes manufacturers in India play a critical role in global textile supply chains.

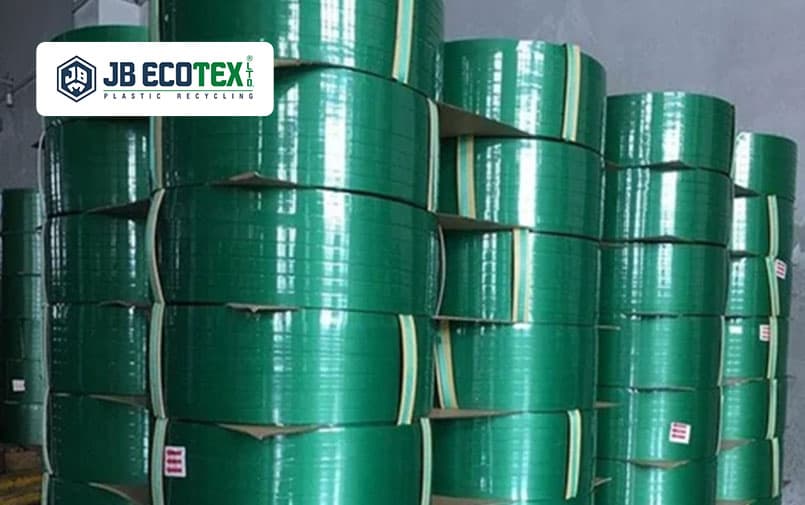

3. Industrial Strapping and Packaging

PET flakes are a preferred input for manufacturing industrial straps used in logistics. These straps secure heavy loads, replacing steel in many applications.

- Green flakes are common here.

- Uniformity and tensile performance are crucial for reliability.

For PET flakes buyers, this is an application where material strength matters as much as cost efficiency.

4. Automotive and Electronics

Automotive manufacturers use PET flakes in non-structural applications such as seat fabrics, insulation, and acoustic panels. Electronics use rPET derivatives in casings and insulation.

While smaller in scale than packaging or textiles, these sectors are growing steadily due to sustainability commitments.

5. Resin and Film Production

Clear PET flakes are feedstock for rPET resins. These resins then go into bottles, sheets, and films.

Film producers value PET flakes for:

- Transparency in display packaging.

- Barrier properties in multilayer applications.

- Adaptability across food and pharma industries.

For every PET flakes manufacturer, supplying clear flakes with controlled PVC levels is essential for this sector.

Regulatory Mandates and PET Flakes

PET flakes have become central to compliance:

- India → Plastic Waste Management Rules require brands to meet specific recycled content under EPR.

- EU → Single-Use Plastics Directive sets strict recycled-content goals for PET bottles.

- USA → FDA approvals allow the use of recycled PET in direct food-contact applications when produced under specific processes.

This makes sourcing from a dependable pet flakes manufacturer more than a cost decision—it is a compliance decision.

Challenges Manufacturers Face

Even with their potential, PET flakes present unique challenges:

- Supply bottlenecks due to rising demand.

- Variation in quality from informal recyclers.

- Contamination risks with PVC, metals, or mixed plastics.

- Cost fluctuations linked to virgin PET pricing.

For PET flakes buyers, selecting the right partner reduces these risks. Reliable suppliers offer consistent quality and verified processes, which are essential for smooth production.

PET Flake Variants: Choosing the Right One

Manufacturers often select flakes based on application:

1. Clear Hot Washed Flakes

- Bottle-to-bottle, food trays, films.

- Low PVC, high transparency.

2. Green Hot Washed Flakes

- Textile yarn, straps, non-food packaging.

- Preferred in extrusion applications.

3. Mixed-Colours Hot Washed Flakes

- Foam, straps, non-food containers.

- Uniformity in size with cost advantages.

This segmentation helps every PET bottle flakes buyer match the right flake to the right process.

Sustainability and Consumer Expectations

The role of PET flakes extends beyond factories and production lines. They connect directly to how consumers perceive brands and packaging.

Today’s consumers look for packaging that communicates responsibility. Words like “100% recyclable” or “made with recycled PET” are no longer fine print. They are prominent on labels and often influence purchase choices. This change has made recycled content a visible part of brand identity.

PET flakes enable this shift. By serving as the feedstock for resins and fibers, they provide manufacturers with traceable recycled content. This allows brands to confidently communicate their use of circular materials. Transparent bottles made from recycled resins derived from PET flakes carry an environmental story that consumers recognize.

For businesses, this is more than marketing. It strengthens trust and aligns products with sustainability commitments. PET flakes make it possible to turn a compliance requirement into a consumer-facing advantage. They are the link that allows a package to both function effectively and demonstrate responsibility on the shelf.

Buyer’s Guide: What PET Flakes Buyers Should Evaluate PET Flakes Suppliers

Every PET flakes buyer faces the challenge of selecting the right supplier. With growing demand and stricter compliance requirements, careful evaluation ensures consistency and reliability.

Here are key factors buyers should assess:

-

Moisture Content

Flakes should maintain less than 1% moisture to prevent issues during extrusion. PVC and Metal Content

Clear flakes for bottle-to-bottle recycling must have PVC levels below 35 ppm and metal content under 5 ppm to meet safety standards. - Flake Size

Uniform size between 2–12 mm supports stable melting and extrusion. - Supply Consistency

Buyers should confirm that the supplier can match their production schedules without variation in flake quality. - Compliance Documentation

Packaging manufacturers require clear evidence that flakes meet national and international regulatory expectations.

By using this checklist, manufacturers can align their sourcing strategy with both technical and compliance needs. For PET flakes manufacturers in India, transparency in these parameters strengthens long-term partnerships with converters, resin producers, and textile companies.

Comparing PET Flakes with Other Material Streams

Manufacturers often evaluate different raw material options. Understanding how PET flakes compare with virgin PET and other recycled streams helps clarify why flakes have gained such a central role in packaging and textiles.

PET Flakes and Virgin PET Flakes

Virgin PET has been the foundation of packaging and textiles for decades. It is produced from petroleum-based inputs and is valued for its consistency and the fact that regulatory approvals for its use are already in place. Many manufacturers continue to rely on it, particularly when uniform performance is required.

PET flakes, by contrast, represent the shift toward recycled content. They are produced from used bottles that are collected, washed, and processed into uniform fragments. Their growing role is tied to compliance targets and sustainability goals. Regulations now require manufacturers to use a certain percentage of recycled content, and PET flakes make this possible without changing existing production systems.

- Virgin PET → long-established, petroleum-derived, consistent performance

- PET flakes → recycled feedstock, supports EPR compliance, reduces dependency on virgin inputs

Rather than replacing virgin PET entirely, PET flakes are becoming a stronger presence in the same supply chains, helping businesses balance performance with sustainability obligations.

PET Flakes and Other Recycled Streams

Different plastics follow different recycling pathways. PET flakes stand out because of the maturity of their infrastructure and reliability as a recycled feedstock.

Recycling technology exists for many plastic types, but not all streams are equally advanced.

- Multilayer packaging is challenging to recycle because it combines different materials that are difficult to separate.

- Low-density polyethylene (LDPE) often carries higher levels of contamination, making large-scale recycling less efficient.

PET stands out because bottles are relatively uniform and supported by established collection systems. This consistency makes the production of recycled PET bottle flakes more scalable and reliable than many other streams.

The result is clear:

- PET flakes have become a dominant recycled raw material for packaging, textiles, and resins.

- Other materials are still building the infrastructure needed to reach the same level of adoption

Future Outlook: PET Flakes in 2025 and Beyond

The role of PET flakes is steadily expanding, shaped by technology, regulation, and the search for new applications. What once began as a straightforward recycling process is now evolving into a space of innovation that reaches far beyond packaging.

1. Smarter Sorting with AI

AI-driven vision systems now detect more than 30 plastic variants at 95% accuracy, lifting flake purity and pushing plant yields up by 20% while cutting manual picks by half. Indian startups are overlaying digital watermarks on labels, enabling NIR cameras to read brand-level QR codes and direct each bottle into the correct stream which is key for food-grade PET flakes buyers who demand ≤30 ppm PVC.

2. Precision Washing & Drying

Sixth-generation recycling lines use closed-loop water circuits and infrared drying that shave 0.15 kWh/kg off energy demand and keep moisture under 0.5%. For PET bottle flakes buyer audits, the tighter spec translates into predictable IV uplift during solid-state polycondensation, speeding changeovers.

3. Chemical Recycling Gains Scale

Methanolysis pilots now show a 46% cut in global-warming potential versus virgin PET and a 31% lower production cost than glycolysis routes. Depolymerised monomers slot back into existing resin reactors, widening feedstock to include coloured or multilayer scrap once unsuitable for food contact. By 2028, chemical routes are forecast to supply 18% of bottle-grade rPET capacity worldwide.

4. Emerging Applications

- Bio-composites: Blends of recycled PET bottle flakes with jute or hemp fibres reach flexural strengths of 110 MPa, 30% above wood-plastic lumber.

- 3-D printing: Flake-to-filament extruders deliver rPET spools at $1.85/kg, one-third cheaper than virgin ABS while offering 25% higher tensile strength for prototyping.

- Construction: Adding 5% rPET fibre to concrete lifts crack resistance by 40% and lowers density 3%, useful for lightweight blocks.

5. What This Means for Manufacturers

- Prioritise suppliers with AI-enabled sortation and closed-loop wash lines to secure consistent PET flakes quality.

- Explore chemical-recycled feedstock to hedge against clear-flake shortages.

- Pilot rPET-natural fibre composites for secondary packaging or pallets to showcase circular design.

Innovation is turning the humble pet flakes manufacturer into a strategic partner for sustainable growth, positioning flakes not merely as recycled feedstock but as a platform for next-gen materials across packaging, textiles, and beyond. The outlook is clear: PET flakes are moving from being a dependable recycled feedstock into becoming a versatile material for innovation. With regulatory pressure rising and technology making recycling more efficient, flakes will remain a cornerstone of sustainable manufacturing while steadily finding new roles across industries.

FAQs

Q1. What are PET flakes used for?

They are used in resin production, textiles, food packaging, films, and strapping.

Q2. Why do PET bottle flakes buyers prefer hot-washed flakes?

Hot washing reduces contaminants like PVC and adhesives, making flakes safer for downstream applications.

Q3. How do PET flakes manufacturers in India support global demand?

They supply clear, green, and mixed flakes at scale to converters, resin producers, and textile industries worldwide.

Q4. Are recycled PET bottle flakes safe for food packaging?

When processed under approved systems, clear PET flakes are converted into food-grade resins used in bottles and trays.

Q5. What should PET flakes buyers look for in a supplier?

They should check for consistency, compliance documentation, and verified quality parameters.

PET Flakes in India: Opportunities for Manufacturers and Buyers

PET flakes are often hidden in plain sight, but their importance cannot be overstated. They support packaging companies in meeting regulations, help textile spinners deliver sustainable fabrics, and enable industries to align with consumer demand for recycled content.

For every pet flakes manufacturer, the challenge lies in maintaining quality and reliability. For every PET flakes buyer, the opportunity lies in leveraging flakes as the raw material that makes circular manufacturing possible.

As global industries move toward 2025 and beyond, PET flakes will continue to serve as the silent but essential building blocks of sustainable production.