Bridging the Gap: How B2B Recycled Material Integration Is Changing Global Sourcing

What if the real challenge in food-grade packaging isn’t raw material scarcity, logistics, or cost but trust?

Trust that the material in your packaging is safe. Trust that it can be traced. Trust that it meets both consumer expectations and regulatory pressure without throwing off your entire supply chain.

As demand rises for more sustainable packaging, manufacturers are being asked to do something that was once seen as contradictory: make products that are both high-performance and high integrity. The kind consumers can feel good about. The kind regulators can verify. The kind brands want to stamp their names on.

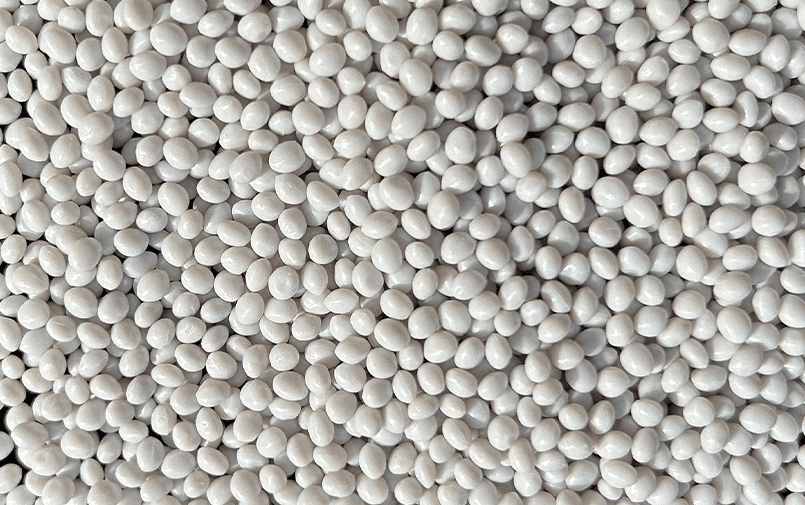

And right in the middle of this shift is a material with quiet potential Bottle to Bottle PET Resin Recycling.

Beyond Recycling: Building Circular Trust

It is no longer enough to say a material is “recycled.” Stakeholders are asking more pointed questions. Where did it come from? Was it food grade? Is it safe for reuse? Can it be traced?

This is where Bottle to Bottle PET Resin Recycling has emerged as a game changer. It is not just about keeping plastic out of landfills. It is about closing the loop with purpose and precision.

By turning post consumer PET bottles back into food grade packaging resins, the material does not just get a second life. It gets credibility. And in a market where trust is everything, that credibility is fast becoming currency.

Why B2B Integration Is No Longer Optional

In the early days of recycled packaging, brand owners carried most of the sustainability burden. They were the ones promising green goals and chasing recyclability stats. But today, that responsibility is shared and increasingly, it is landing on the shoulders of manufacturers who source and convert PET and rPET resins.

Global sourcing is no longer about who can supply cheapest. It is about who can supply consistently, transparently, and compliantly.

That is why B2B integration of recycled PET rPET is no longer optional. It is the foundation for everything from compliance to customer confidence. It allows food packaging manufacturers to track their inputs, validate their processes, and reassure their clients whether that is a multinational brand or a local FMCG player.

And when that integration includes Bottle to Bottle PET Resin Recycling, the benefits multiply. You are no longer just reducing waste. You are actively participating in the Circular Economy.

The Pressure Is Real and Productive

Let’s not sugarcoat it. The regulatory pressure on plastic packaging has never been more intense.

In India and across the world, mandates are shifting. Recycled content thresholds are becoming mandatory. Audit trails are expected. Import export rules are tightening. Whether it is FDA, EFSA, or domestic EPR frameworks, food grade packaging producers must now navigate a complex matrix of requirements.

At the same time, consumer expectations have evolved. Customers no longer look at packaging as just a container. They see it as a statement. About what the brand values. About how safe the product is. About whether it is contributing to the problem or part of the solution.

For manufacturers, this means walking a tightrope. You need material that behaves exactly like virgin resin but carries the environmental benefits of recycled content. You need documentation. You need trust in your upstream suppliers.

You need partnerships, not just transactions.

The India Opportunity

With strong collection networks, emerging recycling infrastructure, and growing policy support, India is becoming a credible sourcing destination for Bottle to Bottle Resins. And the demand for high quality, food grade recycled PET rPET is rising fast.

At JB Ecotex Ltd, we see this shift not just as an opportunity but as a responsibility. Our work with Bottle to Bottle PET Resin Recycling is built around one central idea: make it seamless for packaging manufacturers to adopt recycled content without compromising their standards.

That means ensuring material consistency. Supporting documentation and certifications. And more importantly, staying aligned with what our B2B customers actually need — clarity, quality, and compliance.

Closing the Loop Is a Team Effort

The Circular Economy does not start with slogans. It starts with supply chains that talk to each other.

Converters must know where their resin came from. Resin makers must understand how converters process it. Collection systems must feed into sorting, and sorting into recycling, and recycling into usable raw material again and again.

That level of integration is not always easy. But it is where the future is headed.

Bottle to Bottle PET Resin Recycling is not just about turning yesterday’s

bottle into tomorrow’s. It is about breaking down the old barriers between waste and value. It is about letting nothing go to waste — not material, not process, not trust.

And when done right, it benefits everyone. Brands reduce their footprint. Manufacturers future proof their compliance. Consumers feel confident. And the planet gets a little relief.

The Road Ahead

There are no shortcuts here. High quality sustainable packaging takes planning, investment, and the right partners.

But there is good news. With the rise of verified, food safe Bottle to Bottle Resins in India, the barriers are coming down. Manufacturers no longer have to choose between performance and purpose.

You can meet recycled content targets. You can satisfy global buyers. You can integrate rPET without disruption. And most importantly, you can be ready for what is coming because change is no longer a possibility. It is already happening.

At JB Ecotex Ltd, we are committed to helping you lead that change. Our food grade rPET resins are produced using EREMA VACUNITE technology, a globally recognized standard for safety, purity, and process integrity. We support manufacturers in aligning with EPR compliance mandates and sustainability goals while prioritizing what matters most in food packaging — safety and performance.

Looking to build a compliant, future ready packaging supply chain? Connect with JB Ecotex Ltd today to source reliable, certified Bottle to Bottle PET resins that meet your needs and your values.

Visit www.jbecotex.com or email us at connect@jbecotex.com