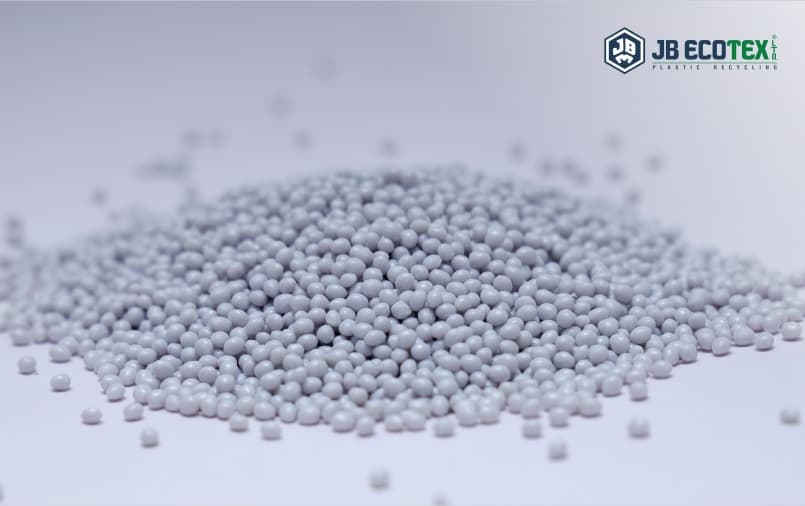

PET Bottle Chips – High-Quality Bottle-Grade Polyester Chips

PET bottle chips, also called PET chips, PET granules, or PET pellets, are the essential raw material for manufacturing packaging, textiles, and food-contact products. At JB Ecotex, we produce PET bottle chips from hot-washed PET flakes using an advanced “super-clean” process. With certifications including FSSAI and USFDA, our chips meet global standards for safety, consistency, and performance.

As a PET chips manufacturer, we supply B2B buyers with bulk volumes tailored for resin converters, preform makers, and textile industries worldwide.

Applications of PET Bottle Chips

Our plastic bottle chips, compliant with rPET resin FSSAI & FDA requirements, are designed for multiple high-performance applications across industries:

- Packaging and Containers – bottles, sheets, and blister packs.

- Injection Molding – beverage preforms and jar manufacturing.

- Textile Yarns & Fibers – polyester staple fibers, filament yarns, and nonwovens.

- Strapping & Industrial Use – recycled polyester chips for straps, films, and engineered plastics.

JB Ecotex PET Bottle Chip Specification

| Parameter | Value | Method |

| Intrinsic Viscosity (IV) |

0.76 – 0.84

|

ASTM D4603 |

| Acetaldehyde (AA)

|

< 1 ppm |

Gas

Chromatography |

| Color (L/b values)

|

L ≥ 82, b ≤ 1 |

HunterLab |

| Bulk Density |

0.85 – 0.90 g/cm³ |

Verified |

Certifications: FSSAI, USFDA, ISO 9001:2015

These specifications detail parameters observed among PET suppliers for plastic applications.

Technology Behind Our Food-Grade PET Bottle Chips

JB Ecotex uses advanced recycling technology, specifically the Erema Vacunite™ system, which combines vacuum-assisted Solid State Polycondensation (SSP) and nitrogen treatment for thorough decontamination and purification. This technology ensures that their recycled PET (rPET) bottle chips meet stringent global food safety standards, making them suitable for food-grade packaging. Their process includes rigorous sorting, cleaning, and contaminant removal to deliver high-purity rPET chips that complies with FSSAI, BIS, and international regulations for direct food contact applications.

Quality Assurance & Packaging

Every batch of our recycled PET chips goes through stringent checks to ensure compliance and consistency.

- Super-clean process for food-contact safety.

- Traceability at every stage, from collection to chip production.

- Custom Packaging Options: 25 kg bags & jumbo bags (1000–1100 kg) available

Global Delivery and Export Support

Serving as a PET chips manufacturer, JB Ecotex supplies to markets across the Americas, Europe, the Middle East, and Southeast Asia.

- Assistance with export documentation.

- Custom labeling as per buyer requirements.

- Flexible volumes to match production needs.

Why Choose JB Ecotex?

- Over a decade of expertise in PET plastic recycling and resin manufacturing.

- Certified by global authorities (FSSAI approved rPET resin, USFDA).

- End-to-end solutions: from flakes to recycled PET chips and food-grade resins.

- Proven partner for converters, textile mills, and packaging companies worldwide.

FAQs

Q1. What are PET bottle chips used for?

PET bottle chips are used to produce beverage preforms, food containers, polyester fibers, strapping, and packaging films. They are an essential raw material for both food-grade and industrial applications.

Q2. How are rPET chips processed from bottles?

Used PET bottles are collected, washed, and converted into flakes. These flakes undergo a super-clean recycling process, then pelletized into PET bottle chips suitable for resin conversion and packaging production.

Q3. Compare bottle-grade PET chips by intrinsic viscosity (IV).

Bottle-grade PET chips typically have an intrinsic viscosity between 0.76–0.84. This property determines melt strength and is crucial for applications like preforms, bottles, and packaging sheets.

Q4. What is the typical PET bottle chips price in India?

PET bottle chips price in India varies with grade and volume. Bulk buyers often negotiate rates per kg, influenced by resin demand, feedstock costs, and international market conditions.

Q5. Who are the buyers and suppliers of PET chips for food-grade bottles?

Food-grade PET chips are purchased by beverage bottlers, packaging manufacturers, and resin converters. Suppliers include certified PET chips manufacturers who meet FSSAI, EFSA, and USFDA food-contact safety requirements.

Q6. What is the HSN code for PET bottle chips?

The HSN code for PET bottle chips generally falls under 3907, which covers polyesters in primary form, including resins, granules, chips, and recycled polyester materials.

Q7. What is the difference between PET flakes and PET chips?

PET flakes are the first recycled form after bottle washing, while PET chips are further processed, purified, and pelletized into rPET resins for textile and direct food-contact applications.

Q8. Do PET bottle chips suppliers in India export globally?

Yes, certified PET chips manufacturers in India export globally, supplying to packaging, textile, and resin industries across Europe, Southeast Asia, and the Middle East with full documentation support.

Q9. What are the applications of PET bottle chips in textiles?

In textiles, PET chips are converted into polyester fibers and filament yarns, used for clothing, nonwovens, carpets, and industrial textiles. Their durability and consistency make them globally preferred.

Q10. How do PET chips differ from PET granules or pellets?

PET chips, granules, and pellets are interchangeable terms referring to polyester in solid form. Differences arise in end-use applications, but all serve as feedstock for packaging and fiber production.

Q11. What technology does JB Ecotex use to produce food-grade PET bottle chips?

JB Ecotex uses advanced EREMA VACUNITE® technology with vacuum and solid-state polycondensation for high-purity, food-grade recycled PET chips for the global packaging industry.

Q12. Are PET chips, resins, granules, dana, and pellets all the same thing?

Yes, they refer to similar forms of PET, but usage varies by region and industry. PET resins, PET granules, and PET pellets are often interchangeable terms for small, processed PET pieces used in manufacturing. Terminology depends on local preferences and end use, with all indicating raw material for producing PET products. Differences, if any, are subtle and based on shape or size rather than composition. This nuance helps clarify that all are forms of PET polymer prepared for various industrial processes.

Q13. What exactly are plastic bottle chips?

Plastic bottle chips are small PET plastic resins made from new or recycled sources like JB Ecotex’s high-quality recycled PET chips, used in bottles and packaging.

Q14. What do recycled polyester chips mean?

Recycled polyester chips, such as JB Ecotex’s rPET resin, come from processed PET waste turned food-safe for packaging with FSSAI and USFDA compliance to meet global standards.

Q15. Who supplies PET plastic in Tamil Nadu?

Buyers in Tamil Nadu, like the rest of the nation, can reach out to JB Ecotex as a supplier of recycled PET chips and rPET resin for various industries.

Q16. How much do PET chips cost in Bangladesh?

JB Ecotex’s recycled PET chips are competitively priced, with Bangladesh pricing influenced by quality, quantity, and market demand for rPET resin.

Q17. What machines do they use to make PET chips?

JB Ecotex uses advanced machines like the EREMA Vacunite® system to produce food-grade recycled PET bottle chips (rPET resin) safely and efficiently.