PET Bottle Recycling: Why Mechanical and Chemical Recycling Must Coexist for a Truly Circular Future

Understanding the Changing Landscape of PET Bottle Recycling

PET bottle recycling is entering a new phase where demand, regulations, global commitments, and packaging choices are reshaping how the industry thinks about circularity. Brands want secure access to food-grade recycled PET. Governments are setting recycled content targets. Consumers are becoming more aware of the footprint of every bottle they touch. This shift is not temporary. It is a structural change in how packaging systems operate.

At the centre of this shift is the reality that PET bottle recycling must rise to meet expectations that are higher than ever. The system must convert diverse feedstock into reliable materials that support packaging, textiles, consumer goods, and several new applications. Countries with well-sorted streams and countries with mixed waste both need stable pathways. Packaging made with eco-friendly food packaging requires safe, consistent, and traceable recycled inputs. These requirements place new pressure on the industry.

Mechanical recycling has been the backbone of the recycled PET journey. Chemical recycling is now emerging as a strong partner for complex feedstock and long-term volume growth. Together, they expand what can be returned to the loop. JB Ecotex focuses on high-quality mechanical recycling, including food-grade resins, through advanced decontamination. JBrPET, the one hundred percent subsidiary of JB Ecotex, is working on chemical recycling pathways that help recover value from PET that mechanical systems cannot always convert.

The evolution of PET bottle recycling needs both.

How Mechanical Recycling Shapes the Foundation of PET Bottle Recycling

Mechanical recycling has grown into a mature and dependable system because it is rooted in physical transformation. Bottles collected from consumers move through sorting, washing, label removal, and shredding into flakes. These flakes are then processed into new forms like rPET granules, recycled pellets, or food-grade resins through controlled thermal and solid-state steps. Large parts of the world depend on this method because it builds material loops with predictable quality.

Mechanical recycling supports several needs in PET bottle recycling:

1. Process familiarity across the value chain

Converters, brand owners, and recyclers understand the pathways, quality boundaries, and cost structures. This creates stability, which helps expand eco-friendly food packaging.

2. Strong compatibility with bottle-to-bottle applications

With advanced decontamination and technologies like EremaVacunite with SSP, mechanical systems achieve food-grade safety when input quality is managed, and plant standards are maintained. JB Ecotex follows high-precision steps in its mechanical process that support consistent resin performance.

3. Value retention for clean feedstock

Clean PET bottles retain good polymer properties, and mechanical systems preserve much of that value.

Mechanical recycling continues to be the primary source of high-quality rPET because it operates reliably, preserves polymer integrity where feedstock allows, and meets a large share of the industry’s needs.

The Expanding Role of Chemical Recycling Within PET Bottle Recycling

The global conversation on circularity has made one point very clear. Not all PET waste is clean, sorted, or free from contamination. Countries face challenges such as multilayer labels, coloured bottles, residues, and packaging formats that complicate sorting. These materials hold value, but recovering that value through purely mechanical means is difficult.

Chemical recycling of plastics offers an additional path. It works by breaking PET down into monomers or intermediates. These streams can then be repolymerised to produce PET that performs like virgin material. JBrPET, the chemical recycling arm of JB Ecotex, focuses on technologies that permit the recovery of value from PET that mechanical systems may struggle with.

The importance of chemical recycling in a circular PET system comes from its unique strengths:

1. Broader acceptance of feedstock

Chemical recycling works with PET that may be mixed, coloured, or contaminated. This widens the total pool of material that can be brought back into the loop.

2. High-purity outputs

Breaking down the polymer to monomers helps remove contaminants. This purity helps support food-grade applications when regulatory approval pathways are followed.

3. A link between collection realities and circularity goals

Countries with heterogeneous waste streams often struggle to keep bottles clean through collection.

Chemical recycling gives these regions an alternative route for challenging feedstock. Chemical recycling adds depth to the ecosystem. It does not replace mechanical recycling. It supports it by ensuring more PET can return to productive use.

Why Both Pathways Are Required for a Truly Circular PET Future

Circularity succeeds when systems fit the realities of feedstock, infrastructure, and application needs. Relying on a single pathway produces bottlenecks. Combining mechanical and chemical recycling builds resilience.

1. Feedstock diversity requires flexible solutions

Mechanical recycling continues to serve clean PET bottles effectively. Chemical recycling manages materials that fall outside this range. Together, they capture a higher percentage of total PET waste. This increases the availability of PET resin pellets and supports a steady supply.

2. Expanding supply for food-grade materials

Eco-friendly food packaging needs resin that meets strict guidelines for migration limits, decontamination, and traceability. Mechanical recycling meets these requirements when conditions are right. Chemical recycling helps when the feedstock is challenging. Their coexistence builds a more reliable supply for food-grade packaging.

3. Stability for converters and brand owners

Converters need consistent resin specifications. Brand owners need long-term security. Mechanical systems provide stability today. Chemical systems add future adaptability. Combining both builds confidence in the circular PET vision.

4. Infrastructure utilisation and expansion

The world has invested heavily in mechanical recycling. This infrastructure carries significant capacity. Chemical recycling expands overall capability without displacing what already works well. Both types of plants can operate side by side to create higher total circularity.

5. Rising regulatory expectations

Regions such as the European Union, the United States, and parts of Asia are enforcing minimum recycled content requirements. India is strengthening EPR frameworks. Fulfilling these commitments depends on strong PET bottle recycling systems. A single technology cannot bridge the volume gap. Both technologies working together can.

6. Market stability and risk reduction

Feedstock purity fluctuates. Collection volumes change. Packaging formats evolve. A system that uses both mechanical and chemical recycling can adjust more easily. It spreads risk and supports long-term circularity goals.

7. Better utilisation of challenging waste

Mechanical systems handle the clean fraction. Chemical recycling of plastics takes care of the part that is difficult to sort or decontaminate. This reduces landfill pressure and supports broader recovery.

Detailed Processes Behind Mechanical and Chemical Recycling

The circular PET ecosystem depends on clear and dependable processing routes that convert post-consumer bottles into high-value materials. The two main pathways, mechanical recycling and chemical recycling, work in different ways but serve a shared purpose. A full understanding of these processes helps explain why they complement each other and why they strengthen PET bottle recycling as demand for food-grade rPET rises across global markets.

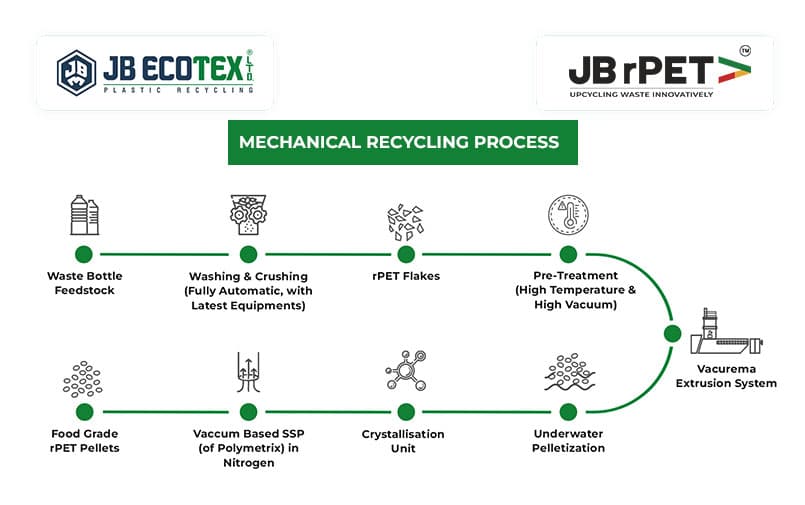

Mechanical Recycling Process of PET

Mechanical recycling converts PET bottles through physical transformation. The polymer chain remains intact, so the steps focus on cleaning, separation, size reduction, and controlled thermal treatment. The process includes the following stages:

1. Collection and Sorting

Bottles from municipal systems, deposit programs, or private collectors enter sorting lines. Optical sorting units identify PET through infrared detection. Colour sorters remove green and other coloured bottles. Caps, rings, labels, and contaminants are diverted to keep the PET stream clean.

2. Cleaning and Pre-Processing

Bottles pass through dry and wet cleaning systems. Label removers detach shrink sleeves and adhesives. Pre-wash units remove dust, sugars, and residues to protect later process equipment. Consistent cleaning supports the production of rPET flake that converters depend on for film, sheet, and packaging applications.

3. Size Reduction

Clean bottles move to granulators, where rotating blades cut them into uniformly sized flakes. Stable flake size improves washing efficiency and helps maintain predictable behaviour during extrusion or pelletising.

4. Hot Wash and Intensive Cleaning

Flakes are washed with controlled temperature water and detergents that remove glue, oil, and remaining contaminants. Friction washers apply mechanical force to clear fine residues. This step determines the clarity and stability needed for eco-friendly food packaging applications.

5. Drying and Separation

Mechanical dryers and air classifiers remove moisture and lightweight particles. High-quality flakes enter refinement stages where metal detectors and fine filters ensure purity.

6. Melt Filtration, Extrusion and Pelletising

Flakes destined for recycled pellets are melted under controlled conditions. Melt filters capture very fine contaminants. The material is extruded into strands and cut into pellets. These pellets act as reliable input for converters and help stabilise the supply of PET resin pellets for several applications.

7. Solid-State Polycondensation (SSP) for Food-Grade Applications

Food-grade systems use SSP to rebuild molecular weight and remove absorbed contaminants. High temperatures under inert gas flow create polymer stability suitable for bottle-to-bottle production. Plants like JB Ecotex use carefully controlled SSP to deliver material that meets standards for food contact.

Mechanical recycling supports most of today’s circular PET output because these steps have been proven at scale. The process enables consistent production of rPET flake and pet resin pellets that supply packaging, textiles, and consumer goods.

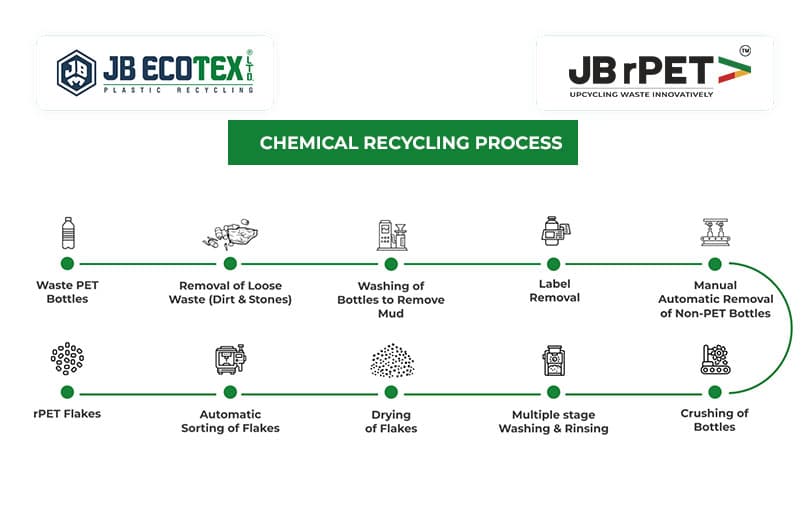

Chemical Recycling Process of PET

Chemical recycling of plastics follows a different pathway. Instead of transforming the polymer physically, it breaks PET down into its building blocks. This allows recovery even when the feedstock is mixed, coloured, or contaminated. JBrPET, the one hundred percent subsidiary of JB Ecotex, is developing technologies aligned with this pathway.

Chemical recycling pathways vary by technology, but the overall sequence includes:

1. Feedstock Preparation

PET from diverse sources enters pre-cleaning steps that remove large contaminants. Full sorting by colour or clarity is not required at the same level as mechanical recycling. This allows the system to process materials that mechanical lines may not prioritise.

2. Depolymerisation

PET is broken down through glycolysis, hydrolysis, or methanolysis, depending on the chosen route. Heat, catalysts, and controlled reaction conditions convert polymer chains into monomers or depolymerised intermediates. These monomers match or closely resemble the inputs used in virgin PET manufacturing.

3. Purification

To achieve the quality required for new polymerisation, monomers undergo filtration, distillation, and chemical purification steps. These stages remove additives, inks, multilayer components, and contaminants that entered the waste stream.

4. Re-polymerisation

Purified monomers are polymerised in reactors similar to virgin PET production. The output has properties comparable to primary PET, including intrinsic viscosity, clarity, and strength. This supports high-performance uses and aligns with the long-term needs of circular packaging.

5. Integration with Downstream Processes

Once polymerised, the material can be converted into flakes, pellets, or resin suitable for packaging and fibre. This forms a complete loop where PET, which once held limited value, becomes a new input for several industries.

Chemical recycling increases the total amount of PET that can be recovered. The process adds flexibility to global recycling and supports future growth where waste stream variability remains a challenge.

Why These Processes Strengthen Circularity Together

Mechanical recycling manages clean PET streams with strong efficiency. Chemical recycling expands recovery to PET that mechanical systems cannot process easily. Together they ensure that pet bottle recycling does not depend on a single pathway. Each technology supports circularity from a different angle. The combination leads to higher total output, better utilisation of collected waste, and a stronger foundation for eco-friendly food packaging across global markets.

Building a Future Where Both Technologies Work Together

The next stage of circularity is not defined by preference for one technology. It is defined by the ability to align both technologies with real-world conditions. JB Ecotex and JBrPET show how this collaboration can emerge. Mechanical processes offer dependable production of food-grade resins. Chemical pathways expand the reach of recycling across more PET types.

Both reinforce each other when the system is designed well.

1. Feedstock sorting and channel optimisation

Highly clean, clear bottles are ideal for mechanical recycling. They enter mechanical lines at JB Ecotex to produce flakes and food-grade resins. Mixed or challenging PET can move toward chemical recycling under JBrPET.

2. Stronger bottle-to-bottle performance

Mechanical systems continue to support bottle-grade resin efficiently. Chemical systems can recover material that mechanical lines are unable to process. This combination protects overall bottle-to-bottle output.

3. Higher total yield

A balanced system reduces losses. Every stage extracts value. This supports companies that require steady streams of recycled content.

4. Shared quality frameworks

Food-grade materials must meet recognised standards. Mechanical recycling meets them with advanced decontamination. Chemical recycling meets them by breaking down polymers and repolymerising them. Both share the same goal, although they follow different paths.

The Path Ahead for PET Bottle Recycling

The path ahead for the industry will be shaped by technology integration. PET bottle recycling will continue to support bottle-to-bottle systems. Mechanical recycling will remain central. Chemical recycling will grow as waste streams become more complex. The combination will define supply, safety, and sustainability in future packaging markets.

Converters, recyclers, and brand owners will need systems that adapt. JB Ecotex and JBrPET demonstrate how such systems can be built. Their roles are distinct. Their contributions support the same goal. A circular PET future becomes more achievable when both technologies work in harmony.

As demand for eco-friendly food packaging increases, the pressure on the industry to deliver safe, high-quality recycled materials will rise. Meeting that expectation requires flexible, dependable solutions. Mechanical recycling provides the strength of an established practice. Chemical recycling offers the capability to handle new challenges. Their coexistence ensures that valuable material resources continue to circulate.

The future of PET bottle recycling depends on the synergy between both approaches. A circular PET ecosystem becomes stronger when each technology contributes its strengths in a coordinated manner.