Connecting with Recycled PET Flakes Buyers: B2B Sourcing & Export Tips

Plastic is Here to Stay, Responsibly

Every time a product leaves the factory floor, it travels wrapped in protection. That protection is almost always plastic. Not because it’s perfect, but because nothing else balances weight, cost, and durability the same way. Packaging is the stage where plastic shows its influence most clearly; it keeps water safe to drink, medicines secure to use, and food fresh to eat.

And yet, the story of plastic has been overshadowed by waste. Headlines equate it with pollution, while regulators push for stricter controls. The reality is more complex. Plastic isn’t disappearing. It’s evolving.

For PET regrind buyers, this evolution means opportunity. By sourcing recycled PET, manufacturers can meet the rules shaping tomorrow’s markets and the expectations of consumers who now check labels as carefully as price tags.

This blog explores how packaging businesses can navigate laws, assess suppliers, and connect with recycled PET flakes buyers worldwide to turn plastic from a liability into a long-term asset.

Sourcing for PET Regrind Buyers: What Matters Most

For PET regrind buyers, sourcing is not only about price but also about consistency, compliance, and long-term collaboration. Packaging manufacturers, whether in food and beverages, home care, or industrial sectors, must evaluate several aspects before purchasing.

Key considerations include:

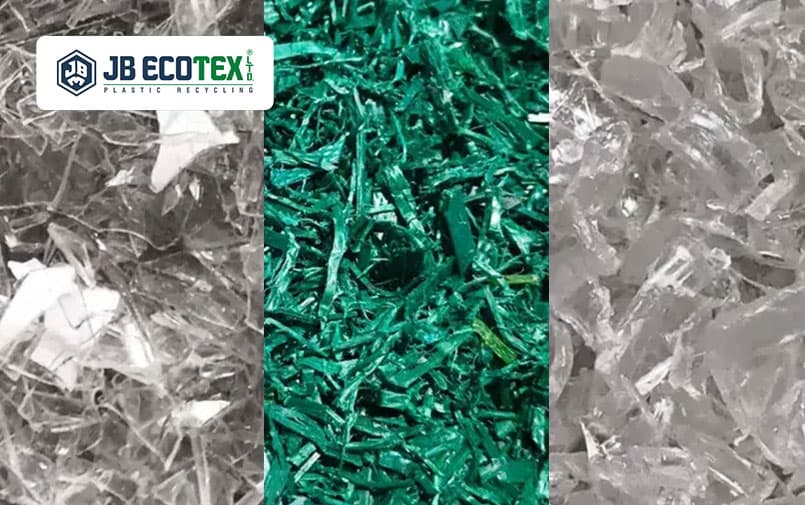

- Material type: options range from mixed colors PET flakes to clear and colored PET flakes purchasers often require. Others source unwashed PET flakes buyers or PET fines bulk buyers for specific applications.

- Certifications: ensuring compliance with food safety norms, such as FSSAI or FDA, when materials are used for direct contact packaging.

- Traceability: knowing the origin of recycled PET supports accountability and builds trust.

- Consistency in supply: packaging runs cannot afford interruptions, making reliable recycled PET flakes buyers relationships essential.

The sourcing process must balance these practical aspects with broader compliance requirements and consumer expectations.

Market Context: Packaging and PET Demand

Packaging is the single largest end-use of PET and rPET. For PET regrind buyers, this demand shows no sign of slowing down. Recent market reports highlight:

- Global PET recycling capacity has expanded steadily in the last five years, with Asia-Pacific leading growth.

- Food and beverage packaging remains the top consumer of recycled PET.

- Plastic flakes buyers in North America and Europe increasingly seek traceable and certified inputs to meet local mandates.

This context reinforces why packaging converters are building long-term partnerships with recycled PET flakes buyers to maintain steady supply chains.

Navigating Global Laws: Impact on PET Regrind Buyers

Governments worldwide are introducing laws to minimize plastic waste and encourage recycling. These regulations directly affect PET regrind buyers and downstream manufacturers.

- European Union: The Single-Use Plastics (SUP) Directive and mandatory recycled content targets in PET bottles.

- India: Extended Producer Responsibility (EPR) rules require Producers, Importers, and Brand Owners (PIBOs) to ensure recycling of a set percentage of their plastic footprint.

- United States: State-level mandates, such as California’s law requiring recycled content in plastic beverage containers.

For PIBOs, this means aligning sourcing strategies with these frameworks. For manufacturers, it creates demand for materials that are already compliant, such as flakes with certifications and verifiable recycling processes. For consumers, it translates into visible changes: bottles, trays, and packaging that are safe, traceable, and demonstrably sustainable.

Buyer Profiles and Needs in the PET Ecosystem

The buyers of PET regrind fall into distinct categories, each with its own requirements:

- Food and Beverage Packaging: Need materials suitable for direct food contact, often preferring hot-washed and traceable flakes.

- Home and Personal Care: Value supply consistency and color flexibility, where mixed colors PET flakes or colored PET flakes purchasers become relevant.

- Industrial Packaging: Often buy in bulk, making them closer to PET fines bulk buyers or wide spec PET resin suppliers, where cost-efficiency matters more than clarity.

Across all categories, buyers demand regulatory compliance and safety. Consumers increasingly look for packaging backed by real environmental commitments, meaning businesses must show visible action rather than statements.

Technical Parameters PET Buyers Evaluate

Before confirming any order, PET regrind buyers check technical details that define usability:

| Parameter |

Why It Matters |

Common Buyer Expectation |

| Intrinsic Viscosity

(IV) |

Affects strength and

processing |

0.76–0.84 dL/g for food-grade |

| Moisture Content |

Impacts melt flow and final product |

Below 0.5% for packaging use |

| PVC Contamination |

Causes yellowing and weak points |

< 50 ppm for food-contact |

| Color Sorting |

Determines clarity or

opacity |

Mixed colors PET flakes for opaque, clear for bottles |

| Packaging Format |

Simplifies transport

and storage |

1000–1100 kg jumbo bags |

These parameters ensure manufacturers receive material aligned with their production and compliance needs.

PET Flakes Sourcing Considerations for B2B Buyers

Manufacturers sourcing from recycled PET flakes buyers must pay attention to the nuances of PET flakes and resin markets:

- Types of Flakes: Washed vs. unwashed, clear vs. colored, fines, and wide spec resins. Each serves a different industrial purpose.

- Bulk vs. smaller consignments: Large consignments reduce per-unit cost but come with logistical complexities, including customs clearance and warehousing.

- Regulatory compliance: Importing unwashed flakes into certain countries faces restrictions due to contamination concerns.

- Documentation: Export processes require accurate shipment records, waste codes, and country-specific compliance documents.

These are real-world challenges that PET regrind buyers navigate daily. They highlight the importance of transparent suppliers who can communicate specifications clearly.

Cost Drivers in PET Sourcing

Price differences between suppliers often come down to underlying material and processing factors. Common drivers include:

- Color: Clear flakes usually cost more than mixed-colour PET flakes.

- Washing Process: Hot-washed flakes involve added water and energy use.

- Contamination Risk: Lower PVC levels require more sorting effort.

- Transportation: Long-distance shipping increases landed costs.

- Order Size: Pet fines bulk buyers generally secure lower per-unit pricing, while smaller consignments carry higher handling charges.

Understanding these drivers helps buyers compare quotes more effectively.

Export Tips for PET Regrind Buyers: Making It Seamless

Global sourcing of recycled PET involves navigating multiple layers of regulation. Recycled PET flakes buyers and exporters must address:

- Customs clarity: Each destination has its own documentation standards. Missing certificates delay shipments.

- Material specs: Clear agreements on requirements help when dealing with unwashed PET flakes buyers or colored PET flakes purchasers, where post-processing differs.

- Networking: Building reliable B2B relationships through industry fairs, associations, and digital procurement platforms allows buyers to compare wide spec PET resin suppliers and avoid one-time, high-risk transactions.

- Sustainability reporting: Companies sourcing plastic flakes buyers often need data to report recycled content use for compliance or marketing claims.

Exporting is not only about moving material across borders but also about ensuring that each shipment reflects both environmental responsibility and business reliability.

Documentation and Customs Codes

International trade of recycled PET requires proper documentation and awareness of customs rules. Shipments typically fall under Harmonized System (HS) codes for plastic waste or secondary raw materials. Unwashed PET flakes buyers should note that European ports apply stricter controls under the Basel Convention to limit contamination.

Commonly requested documents include:

- Bill of Lading and Packing List

- Import permits where required

- Certificates of conformity or recycling

- Waste classification codes specific to each country

Clear documentation reduces delays and strengthens confidence between exporters and recycled PET flakes buyers.

Sustainability and Brand Story in PET Sourcing

Responsible sourcing connects directly to brand reputation. Manufacturers using recycled PET in packaging are not just meeting compliance but also aligning with consumer demand for accountability.

Examples of sustainability practices that support this shift:

- Using renewable energy, such as solar or wind, in recycling operations.

- Operating zero-liquid-discharge systems that ensure water conservation.

- Partnering with recycled PET flakes buyers to close the loop in local and global supply chains.

For colored PET flakes purchasers and wide spec PET resin suppliers, this alignment helps brands tell an authentic story, one that consumers trust and regulators recognise.

Actionable Tips for Buyers and Sellers in rPET Trade

For PET regrind buyers, a few practical checkpoints make sourcing more efficient:

- Verify supplier compliance: Request documentation on traceability, washing, and food-grade suitability.

- Understand material specifications: Mixed colors PET flakes may work for some applications, while food-grade demands clear flakes.

- Check bulk order processes: Pet fines bulk buyers often need clear contracts on packaging, transport, and customs clearance.

- Ask sustainability questions: Engage suppliers on energy use, waste management, and water treatment to ensure alignment with consumer expectations.

For suppliers, clarity in communication is the most effective strategy for long-term partnerships.

Buyer Checklist

When sourcing recycled PET, structured questions help reduce risk and build stronger supply chains.

10 Questions Every Buyer Should Ask Suppliers

- What is the IV range of your flakes?

- Can you share certificates for food-grade suitability?

- How do you manage PVC contamination levels?

- Do you supply mixed colors PET flakes as well as clear?

- Are flakes washed or unwashed, and what process is used?

- What packaging formats are available for PET fines bulk buyers?

- Who are your logistics partners and what are lead times?

- Can you provide sustainability data on energy and water use?

- What is your policy for rejected consignments?

- How is material traceability maintained across the supply chain?

This checklist helps PET regrind buyers make informed decisions and establish reliable partnerships.

Responsible Plastics For a Responsible Future

Plastic will continue to be a core part of global packaging. The challenge is ensuring it contributes to sustainability instead of pollution. For PET regrind buyers, this means sourcing responsibly, understanding regulations, and working with suppliers that provide transparency.

Recycling, compliance, and consumer trust are no longer separate priorities. They are interconnected forces shaping how PET and rPET move through global markets.

At JB Ecotex, we view every transaction as part of this broader movement. By enabling manufacturers to connect with reliable recycled PET flakes buyers, the industry can build packaging systems that protect products, respect consumers, and support a circular economy.