Textile-to-Textile (T2T) Recycling: Closing the Loop in Polyester Fibres

Let’s talk about the clothes that never made it to their second life.

A discarded shirt in Tiruppur. A polyester saree dumped outside Dhaka. A mountain of clothing buried in Chile’s Atacama Desert, large enough to be seen from space. We don’t just wear and forget. We pile. And polyester? It takes centuries to break down.

This is the backdrop for the shift to textile-to-textile recycling (T2T recycling) which is an effort not just to reuse, but to truly re-loop. To turn what was once a dead-end garment into viable new fibre, without down cycling it into insulation or industrial rags.

And in 2025, that’s exactly what manufacturers, brands, and stakeholders are watching closely.

What Is T2T Recycling and Why Does It Matter?

T2T recycling refers to the process of recovering post-consumer or post-industrial textile waste and chemically converting it back into usable polyester fibre. Unlike mechanical recycling, which typically starts with PET bottles, T2T tackles the real elephant in the room. Fabric waste.

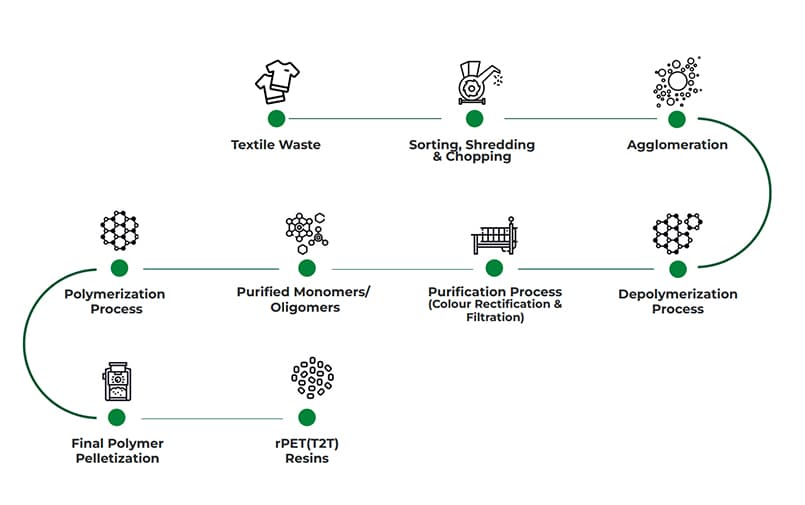

In textile-to-textile recycling, garments are shredded, cleaned, and depolymerised through chemical processes that separate dyes, coatings, and other impurities. The result: a high-grade recycled resin that can be re-spun into new polyester fibres.

This isn’t just recycling. It’s circular textile recycling at its most ambitious turning yesterday’s t-shirt into tomorrow’s active wear, again and again.

T2T vs Virgin Resin: What Buyers Want to Know

As conversations around fibre sourcing become more nuanced, many manufacturers are comparing T2T-derived resin with traditional virgin inputs. For teams focused on quality, traceability, and regulatory alignment, chemical recycling offers a viable route.

The material performance of T2T resins when processed correctly is consistent with virgin resins. With proper polymerisation, melt flow and structural clarity can meet or even exceed standard expectations. This means that for manufacturers seeking performance without the fossil-based origin, T2T is an option worth considering.

Beyond technical specs, buyers are also looking at ESG metrics, waste offsets, and circularity documentation. T2T sits at the intersection of these priorities.

The Scale of the Problem (And the Opportunity)

The textile industry’s waste problem isn’t hidden. It’s worn daily. The numbers are troubling, to put it lightly.

Textile landfills are expanding across the globe from Kenya’s Dandora dump site to the overflowing warehouses of Panipat. Fast

fashion cycles, low-cost synthetics, and a lack of recycling infrastructure mean that only a fraction of discarded polyester ever gets recovered.

T2T Polyester Recycling offers a way forward. It suggests that polyester, despite being synthetic, doesn’t have to be linear. With the right infrastructure, it can be a regenerative material.

JB rPET: Powering Chemical T2T in India

At JB Ecotex, we understood that if real circularity was to happen, the material needed to come full circle. That’s where JB rPET comes into the picture. A 100% subsidiary dedicated to advanced chemical recycling of textiles and PET bottles.

Our system is designed to take in post-industrial and post-consumer polyester waste, remove contaminants, and reprocess the output into high-grade resin through a

closed-loop depolymerisation system.

We call it JBrPET T2T, and it’s our answer to the future of responsible fibre. You can read more about it here.

Chemical recycling works at the polymer level. It breaks down polyester into its base building blocks, removing dyes, coatings, and other impurities. This molecular purity gives T2T resins structural clarity, making them well-suited for applications where consistency and safety matter.

Unlike conventional recycling, JB rPET’s approach is built to ensure colour separation, polymer integrity, and material safety. This makes it suitable for the re-spinning of staple fibre or filament yarn.

Where T2T Polyester Recycling Fits In the Supply Chain

The beauty of textile-to-textile recycling is in how seamlessly it can integrate into the textile manufacturing value chain. Waste collected from garment units, finishing houses, or even end-of-life products can be reintroduced into resin production.

This reduces the pressure on virgin feedstock. It offers brands a more compelling sustainability story. And it gives sourcing professionals a way to meet circularity KPIs with material that matches their existing specs.

T2T recycling is not just a post-consumer fix. It’s also a pre-consumer opportunity.

Benefits for Textile Manufacturers and Stakeholders

- Traceable sourcing: With chemical recycling, batch-level documentation can help establish supply chain transparency.

- Custom-grade compatibility: T2T-derived resins can be tailored for different end uses, offering a material fit for spinning, weaving, or nonwoven conversion.

- Circularity reporting: Manufacturers working with JBrPET T2T can demonstrate alignment with sustainability frameworks without relying solely on PET bottle metrics.

- Long-term security: With increasing scrutiny on plastic-based textiles, T2T Polyester Recycling offers an evolution path that supports future-focused production.

2025 And Beyond: From Experiment to Industry Standard

The industry has just begun to scratch the surface. And yet, T2T recycling is already gaining traction in global supply chain conversations. International regulators are taking note. Major brands are setting T2T content targets. And, manufacturers in India are looking to collaborate with partners who can ensure quality at scale.

A recent report from Ellen MacArthur Foundation outlines that circular textile systems, including T2T recycling, could reduce GHG emissions by up to 45% in the next decade, if adopted at scale.

The next step involves building infrastructure, developing feedstock pipelines, and creating real-world partnerships that move ideas into action.

FAQs: Textile-to-Textile Recycling

1. What is T2T recycling?

T2T recycling refers to textile-to-textile recycling which includes chemically converting old polyester garments and production waste into new raw material for fibre production.

2. What is JB rPET’s role in T2T recycling?

JB rPET is the chemical recycling arm of JB Ecotex. It supports JBrPET T2T by converting textile waste into rPET resin, enabling a more circular polyester ecosystem.

3. How is T2T Polyester Recycling different from PET bottle recycling?

T2T targets fabric waste, not bottles. It uses chemical processes to break down polyester garments, offering a more closed-loop textile solution.

4. Is circular textile recycling viable at industrial scale?

Yes, provided infrastructure, feedstock sorting, and regulatory support continue to evolve. JB Ecotex and JB rPET are committed to building that capability.

Why JB Ecotex Stands by T2T Recycling

Textile-to-textile recycling isn’t a trend. It’s a recovery mission. For every kilogram of fibre that’s reborn, there’s a garment that didn’t end up as landfill.

At JB Ecotex, through JB rPET, we’re not just watching this shift. We’re enabling it with chemical recycling systems that close the loop, one fibre at a time.