How Bottle-to-Bottle Recycling Is Transforming India’s Packaging Industry

There’s something about seeing an empty bottle become a bottle again that feels...different. It’s not just recycling. It’s a full circle. And in India’s fast-changing packaging sector, this circle is starting to reshape the future.

Manufacturers who rely on PET packaging know how high the bar is today. Food-grade safety, traceability, and consumer trust are non-negotiable. At the same time, buyers want their packaging to be sustainable, lightweight, and regulation-ready. The good news? Bottle-to-bottle recycling checks all those boxes and is no longer a Western luxury. It's fast becoming a strategic necessity in India.

From Linear to Loop: A Quiet Shift That Speaks Volumes

For years, the focus in plastic recycling in India was quantity, not quality. Downcycling dominated. Bottles turned into textile fibre, trays, or other non-food applications. But as global pressure mounted and India’s own circular economy targets took shape, that story started to change.

Bottle-to-bottle recycling is now driving a new narrative. One where used PET bottles can re-enter the system as safe, food-grade containers, ready for another round. This shift aligns not just with sustainability goals, but with what global brands and Indian regulators are now demanding: high-quality, traceable, and recyclable packaging.

What Makes Bottle-to-Bottle Different?

The average PET bottle goes through a complex journey in its second life. It isn’t just shredded and molded. It is:

- Collected from post-consumer sources

- Thoroughly cleaned and sorted

- Processed through advanced decontamination systems

- Subjected to strict quality checks and SSP (Solid State Polycondensation)

This PET recycling process ensures that the resulting resin can safely be used again in direct food contact. For B2B manufacturers, this means sourcing resin that fits right into existing packaging lines without compromising on compliance or consumer safety.

What Indian Manufacturers Should Be Watching

In India, bottle-to-bottle isn’t an industry talking point. It’s an emerging operational reality. FSSAI, BIS, and global export standards are all moving toward stricter validation of recycled content in packaging. Manufacturers need suppliers who can meet these standards without greenwashing.

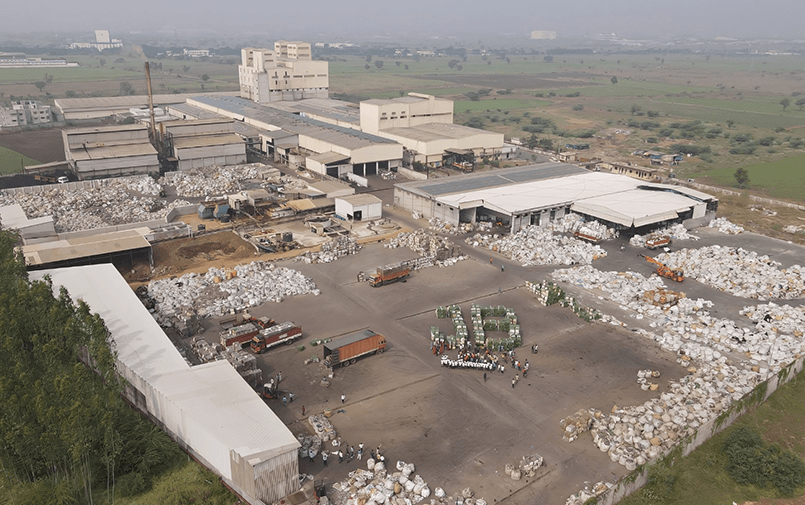

JB Ecotex, for instance, uses Erema’s advanced Vacunite™ technology, which combines vacuum-assisted SSP and nitrogen treatment for enhanced purity. This isn’t just technical fine print. It’s what makes the difference between generic rPET and food-grade rPET that leading brands will accept. Learn more about the difference between virgin and recycled food-grade PET here.

At the heart of this shift lies traceability. Brands want proof—not promises. That means every bottle, flake, and pellet should have a documented past and a safe future.

We also recognize the emerging potential of chemical recycling. Our sister company JBRPET is actively working on producing chemically recycled rPET resins that complement mechanical processes, further enabling a closed-loop, food-safe future for packaging.

What Are Consumers Asking For?

More than ever, consumers are label-checking. They want to know what their packaging is made of. They’re alert to vague terms. If it says "recyclable," they want to know if it’s been recycled. If it says "eco," they expect the science to back it up.

Bottle-to-bottle recycling helps brands meet that bar. It doesn’t rely on assumptions. It puts post-consumer bottles back into bottles, reducing virgin plastic use, improving life-cycle scores, and reinforcing credibility.

From Fibre to Food: Breaking the Old Pattern

India is one of the world’s largest producers and consumers of rPET fibre. But the future of plastic recycling in India lies not just in fibre, but in reclaiming bottles for packaging. This shift helps retain material value, reduce carbon impact, and meet international compliance benchmarks.

And it’s already happening. In our blog, we covered the value of recycled PET in textiles. But in this next phase, the real challenge is upgrading both material quality and accountability bottle by bottle.

Regulatory Winds Are Changing

Extended Producer Responsibility (EPR) in India is shifting from collection to circularity. Draft rules released in 2025 suggest a future where brands may receive credits only for bottle-to-bottle or same-use recycling, not just generic recovery. This will make supply chain alignment more important than ever.

Read more about the draft amendment here.

This is why manufacturers must ask their suppliers: Can your recycled resin go the distance? Can it stand up to audits, compliance checks, and brand-level scrutiny?

What Manufactures Are Asking About recycled B2B PET resins

1. What is bottle-to-bottle recycling and why does it matter for food-grade PET packaging?

Bottle-to-bottle recycling converts used PET bottles back into high-quality food-grade resin suitable for new packaging. This process ensures safety, sustainability, and compliance with global and Indian standards.

2. How does bottle-to-bottle recycling support the circular economy in India?

By enabling repeated use of PET bottles in food packaging, bottle-to-bottle recycling reduces virgin plastic demand and waste, fostering a circular economy focused on material recovery and sustainability.

3. What technologies are used for bottle-to-bottle recycling in India?

Advanced technologies like Erema Vacunite™ ensure thorough decontamination and purification. These systems are crucial to producing food-grade rPET that meets stringent quality and safety requirements.

4. How is chemically recycled rPET different from mechanically recycled rPET?

Chemically recycled rPET breaks down PET polymers to remove contaminants at a molecular level, enhancing purity. JB Ecotex’s sister company, JBRPET, specializes in producing chemically recycled rPET resins.

5. How are 2025 regulatory changes in India affecting bottle-to-bottle recycling?

New draft rules prioritize same-use recycling credits, making bottle-to-bottle recycling essential for manufacturers to comply with Extended Producer Responsibility (EPR) and packaging regulations.

Where We Go Next

The Indian packaging industry is no longer waiting for global trends to arrive. It is creating its own. As circular economy India policies mature, and food packaging norms tighten, bottle-to-bottle recycling will become less of a choice and more of a baseline.

We believe that the next leap forward will not come from capacity alone. It will come from how responsibly we handle what we already have.

Manufacturers looking to stay ahead need to treat rPET not as a fallback, but as a foundation. One that requires investment, collaboration, and a shared belief in the long game.

Because a bottle is not just a container. It’s a commitment. Especially in 2025.

JB Ecotex is part of this journey.. quietly, intentionally, and without shortcuts. If you're a packaging manufacturer preparing for the next chapter, we’d be happy to talk.