Circular Raw Materials in the Global Food Packaging Industry

Most conversations about food packaging begin with design. Labels, shelf life, logistics. But there’s one question more manufacturers are asking today: what is this material made of?

At JB Ecotex, we work with the quiet foundation of that question: the resin. Specifically, B2B food-grade resin that manufacturers use to produce bottles, trays, and containers that must meet safety expectations without missing sustainability targets.

The stakes have changed. Buyers, regulators, and even casual consumers want to know that the materials holding their water, dairy, or ready-to-eat products are safe, traceable, and low-impact. In 2025, the way food-grade rPET trends evolve will directly shape how global sourcing works across the packaging value chain.

Let’s explore what this shift means and why the conversation around B2B food-grade resin has never been more critical.

The Push Toward Safer, Circular Materials

Globally, regulatory bodies have moved from recommendation to regulation. In the EU, EFSA has laid out clearer thresholds for food-contact rPET. In India, FSSAI regulations, along with guidelines for EPR, material origin, and recyclability are getting more structured.

For manufacturers, this adds a new layer of scrutiny. The old question used to be “Can this resin perform?” Now it’s joined by “Can we prove where it came from?” and “Will it pass audit in every geography we supply to?”

That’s where innovations in sourcing matter. And it’s where food-grade rPET trends are making space for new technologies, better batch tracking, and resin systems that support both circularity and compliance.

Why B2B Integration Is the Missing Link

One of the most visible challenges in global sourcing is this: while many brands want sustainable packaging, their suppliers often work in silos. Recyclers, resin makers, converters, and packagers may not be operating with shared transparency. Compliance is a must.

B2B food-grade resin integration helps overcome this disconnect. It allows upstream and downstream partners to build in traceability from the flake to the finished container.

For food-grade applications, this matters. Not just for compliance, but for assurance. Material safety cannot be reverse-engineered after the fact. It needs to be managed from the moment flakes are washed and dried.

At JB Ecotex, this conversation shows up often. Brands are looking to shorten their sourcing cycles, reduce supplier fragmentation, and build longer-term visibility into their resin sourcing.

How Food-Grade rPET Trends Are Redefining Sourcing Criteria

We see some common shifts shaping sourcing strategies:

- More sample validation per batch

- Requests for technical support at the converter stage

- Growing preference for Erema Vacunite-based or similar food-grade processes

- Documentation trails to support EPR and ESG claims

These trends are not limited to global giants. Even regional packaging manufacturers are following the lead of global procurement playbooks.

In short, food-grade rPET trends are defining what makes a resin competitive. Cost and clarity remain important, but they are now part of a larger set of priorities. We aim to ensure that the food-grade rPET resins we provide regulatory requirements that our clients need to fulfill.

What Are the Main Applications and Advantages of PET Chips?

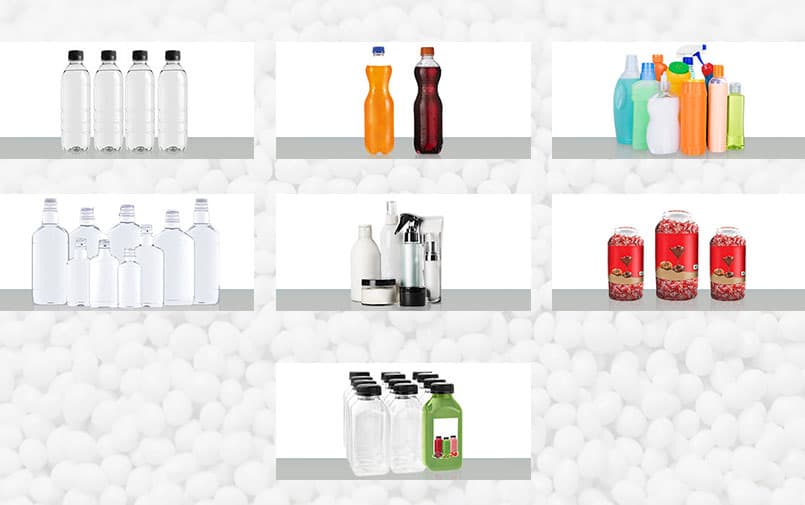

Whether referred to as PET chips, granules, or resins, these materials are the backbone of packaging formats used across:

- Beverage bottles

- Edible oil and milk containers

- Personal care bottles

- Hot-fill juice and sauce packaging

- Preforms for export packaging

Their advantages include high strength-to-weight ratio, excellent barrier properties, recyclability, and relatively low energy requirement during thermoforming. When produced from recycled sources, they support sustainable packaging resin targets without compromising function.

As demand rises for rPET for packaging, B2B buyers are asking more detailed questions about melt flow rate, intrinsic viscosity, and additive load: all factors that vary depending on processing methods. We manufacture mechanically recycled B2B rPET resins that manufacturers in the market are on the lookout for.

Differences Between PET Resins, Chips, and Granules

Functionally, these terms are often used interchangeably. But technically, PET chips refer to small pelletized forms of PET prepared for melting and molding. Resin is the broader category, referring to both virgin and recycled material used for production. Granules may refer to pre-compounded forms ready for extrusion.

In practice, a converter or manufacturer may refer to all three when sourcing. What matters most for food-grade applications is not the label, but process control, flake origin, and transparency in conversion.

The expectation is simple: safer materials with a proven record.

But behind that expectation is a complex web of requirements:

- Food safety certifications

- Country-specific compliance

- Proof of recyclability

- Evidence of responsible sourcing

- And increasingly, carbon and water footprint metrics

This is why global buyers are now asking for B2B food-grade resin options that integrate clean sourcing, standard documentation, and batch-level tracking from day one.

And for consumers, the packaging story is becoming a reflection of the brand. Words like “100% recycled” or “safe for reuse” carry weight only when backed by verifiable sourcing. Brands that deliver this build deeper trust with their customers.

The Future of Food-Grade PET and What It Will Require

The future of food-grade PET will depend on how well the industry builds confidence at scale with adoption of sustainable packaging resin.

We’re also seeing new interest in in-line IV measurement, closed-loop certifications, and collaborative tools to help convert flakes to resin in traceable, consistent ways.

Innovations in rPET resin continue to shape both production capabilities and regulatory confidence. As these technologies evolve, B2B partners will need to stay closely aligned to stay competitive.

At the same time, greater collaboration in rPET for packaging workflows will support faster transitions from prototype to production as well as from promise to delivery.

Frequently Asked Questions

1. What is B2B food-grade resin used for?

B2B food-grade resin is used by manufacturers to create safe, compliant packaging for food and beverage products. It supports applications such as water bottles, dairy containers, and hot-fill packaging.

2. How does food-grade rPET compare to virgin PET?

Food-grade rPET performs similarly to virgin PET in terms of safety and clarity when processed properly. It offers the added benefit of supporting sustainability goals by reducing dependence on fossil-based raw materials.

3. What are the benefits of using rPET for packaging?

rPET for packaging helps brands lower their carbon footprint, comply with extended producer responsibility (EPR) regulations, and align with consumer preferences for recycled content.

4. Are PET chips, granules, and resins the same thing?

These terms are often used interchangeably. PET chips are pelletized forms of PET, while granules and resins can refer to slightly different preparation stages. All are used in the production of plastic packaging.

5. What innovations in rPET resin are shaping the industry?

Innovations include advanced decontamination technologies, in-line viscosity monitoring, and improved traceability systems. These developments are helping B2B suppliers meet food safety and regulatory expectations.

JB Ecotex Is Here To Help

At JB Ecotex, we understand that B2B food-grade resin represents more than just a raw material. It supports food safety, sustainability targets, and brand values.

As food-grade rPET trends continue to evolve, we are focused on clarity, reliability, and partnership. We work with brands and manufacturers who want to align sourcing with performance and responsibility.

For more about our resin options or to explore a partnership,contact us at: