Sustainable Textiles: Growth of Recycled Fibre Industry in India

The textile industry in India has been undergoing a quiet but powerful transformation. At the centre of it all is the growth of recycled fibre industry in India. With increasing environmental awareness and shifts in consumer preferences, companies like JB Ecotex are investing in sustainable pathways specifically in the production and innovation of Recycled Polyester Staple Fibre (RPSF).

The Shift Towards Sustainable Textiles in India

Sustainability in textiles was supposed to be the simple answer.

Recycle materials. Reduce waste. Deliver high-quality fabrics. Done.

At least, that’s what we thought.

Everyone, from large textile manufacturers to smaller startups, began switching to recycled polyester and other sustainable textiles. The objective was straightforward:

- The more we recycle, the less we waste.

- The more we recycle, the more sustainable our products become.

But the path forward hasn’t been entirely smooth.

The textile industry recycling journey is complex. It involves not just replacing virgin raw materials with alternatives like Recycled PET Fibre, but also maintaining consistent performance across applications.

At JB Ecotex, we’ve experienced this evolution first-hand. As one of the companies actively involved in advancing the growth of recycled fibre industry in India, we’ve seen the opportunities as well as the realities.

A New Era: rPET, RPSF and Sustainable Growth

A critical component of this shift is rPET chips, which serve as the foundational material for many recycled products. These chips are manufactured from post-consumer PET bottles, giving new life to plastic waste. Using rPET not only helps reduce dependence on virgin resin, but also aligns with global sustainability benchmarks.

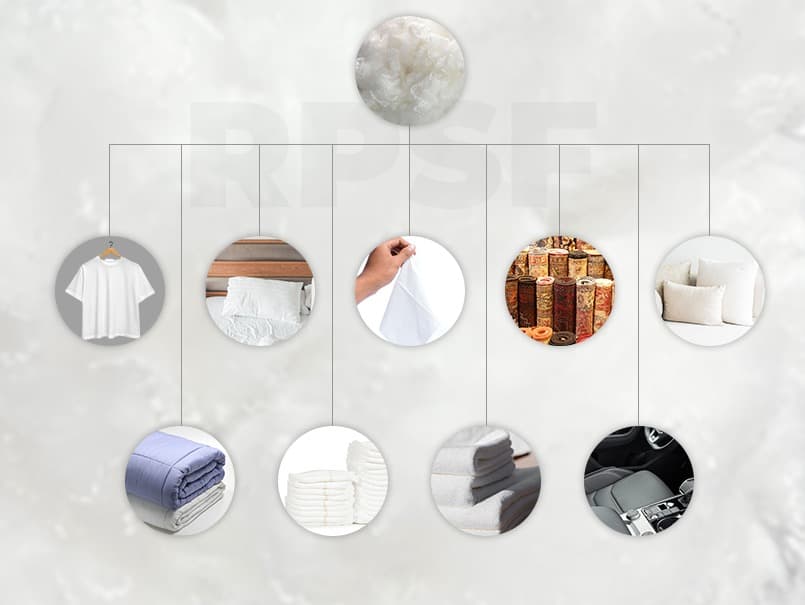

In turn, these chips are transformed into Recycled Polyester Fibre—our area of specialty. We produce RPSF that caters to a wide range of industries, including automotive, apparel, home furnishings, and non-wovens. The RPSF products we offer are engineered with performance in mind, helping our customers move toward more circular production cycles.

Our Range of RPSF Products

We offer an extensive portfolio tailored for industry-specific needs:

1. Hydrophilic Fibre

- Ideal for use in oil filters, hand wipes, and performance apparel

- Absorbs water, adhesives, and chemicals

2. Low Hot Air Shrinkage Fibre

- Maintains stability after high-temperature exposure

- Commonly used in non-woven felt production

3. Micro Siliconized Fibre

- Silicone-treated for softness

- Suitable for bedding items like cushions and quilts

4. Super High Tenacity Recycled Fibre

- Extremely durable and strong

- Used in ropes, cords, and high-strength fibre materials

Each of these products is available in multiple deniers and cut lengths, with standard packing at 350 kgs per bale.

Innovation and Challenges in PET Recycling

The technology behind PET vs virgin plastic is evolving. Advances in innovations in PET recycling allow for better quality, more consistent fibres, and a wider range of end-use applications. That said, the process still has hurdles—contamination, sorting efficiency, and cost competitiveness with virgin plastic being some of them.

At JB Ecotex, we are exploring techniques that further improve the durability, dyeability, and softness of recycled fibres. These are crucial not only for product performance but also for driving larger adoption within the industry.

The move toward recyclable composite materials is also opening up new doors. These materials can be used in technical textiles and industrial applications, making the possibilities broader than just apparel or furnishings.

Plastic Recycling and Its Role in a Circular Textile Economy

India generates millions of tonnes of plastic waste annually. Plastic recycling is no longer a side initiative—it’s a necessity. By integrating recycled PET fibre into the mainstream textile supply chain, we’re not just solving a pollution problem, but actively participating in the growth of a new economy.

The growth of recycled fibre industry in India is not a temporary trend. It’s a sign that manufacturers, brands, and consumers are all thinking differently about what they wear, how it’s made, and where it ends up.

Trends Shaping the Recycled Fibre Landscape in 2025

As we move through 2025, several key trends are influencing the growth of recycled fibre industry in India—not just in production, but across the entire value chain.

1. Brand-Driven Sustainability Commitments

Major fashion and textile brands are setting more aggressive sustainability goals. Many are shifting to materials like recycled polyester fibre and rPET chips, pushing suppliers to scale operations and improve consistency. JB Ecotex is already seeing increased inquiries from manufacturers seeking reliable RPSF products with dyeing flexibility and performance guarantees.

2. Rise in Advanced Fibre Technologies

There’s a growing demand for high-strength fibre materials and advanced fibre reinforcement techniques that support specialized use cases, from automotive to industrial textiles.

3. Focus on Transparent Supply Chains

Textile buyers now ask for traceability—where the fibre came from, how it was processed, and what waste it helped reduce. This is pushing innovations in plastic recycling reporting and driving interest in verified recyclable composite materials.

4. PET Recycling vs Virgin Resin Economics

The PET vs virgin plastic conversation is shifting. Rising global resin costs are making recycled options more attractive. However, ensuring stable quality in recycled PET fibre remains key to this trend sustaining momentum in India.

5. Government and Regulatory Push

Policy developments around Extended Producer Responsibility (EPR) and single-use plastic bans are making recycled content not just preferable but essential. This regulatory support is a tailwind for the recycled fibre industry, helping scale both capacity and awareness.

What the Future Holds

As JB Ecotex continues to contribute to the growth of recycled fibre industry in India, we remain cautious yet optimistic. We believe that with the right mix of innovation, investment, and intention, the path forward can be both profitable and sustainable.

We’re exploring:

1. Enhanced performance across all RPSF categories

2. More efficient manufacturing with reduced environmental impact

3. Collaboration opportunities to co-create fibre solutions with downstream partners

In the future, we see an India where sustainable textiles aren’t an alternative but the standard. And the recycled fibre sector, especially RPSF products, plays a central role in making that happen.