How rPET Chips Are Redefining Food Packaging Safety

Food packaging carries a responsibility that goes far beyond convenience. Every container, tray, or punnet that touches food must protect it from contamination while maintaining freshness and safety. At the same time, packaging is now at the centre of environmental reform. Governments are enforcing Extended Producer Responsibility (EPR) rules, brands are setting recyclability targets, and consumers are asking what their packaging is made from.

Somewhere between those expectations sits rPET, or recycled polyethylene terephthalate. In its refined form, rPET chips have become one of the most important raw materials for sustainable packaging. When used in rPET chips food containers, they bring together two vital goals for the food industry, safety and circularity.

Why the Food Industry Is Moving Toward rPET Chips Food Containers

Until a few years ago, recycled plastics were rarely considered for direct food contact. The fear of contamination and lack of established purification technology kept manufacturers dependent on virgin PET. That perception has changed. Modern recycling systems can now process post-consumer PET bottles into high-purity rPET chips that perform almost like new resin.

These advances have opened the door for food and beverage companies to introduce rPET packaging in their global supply chains. Trays, cups, and containers made from rPET are no longer exceptions. They are becoming the new normal for responsible brands. India is following this shift closely as sustainability frameworks and plastic packaging EPR norms begin linking packaging design with recyclability and recycled content use.

What Makes rPET Chips Safe for Food Containers

Food-grade safety is achieved through technology, not assumption. The safety of rPET chips used in food containers depends on how thoroughly the recycling process removes impurities. Conventional mechanical recycling can clean PET, but super-clean processes go a step further.

In advanced systems such as EREMA Vacunite, used by JB Ecotex, the material is exposed to controlled heat and vacuum conditions that remove volatile residues and rebuild the polymer structure. This method ensures the resulting rPET chips are stable, clear, and safe for conversion into containers, trays, and films.

To confirm compliance, every approved process must meet specific migration limits, which measure how much of any substance could potentially transfer from packaging into food. Only when testing proves that migration remains below regulatory thresholds is rPET cleared for food-contact use. This scientific validation ensures that rPET chips food containers are just as safe as those made from virgin PET.

Regulations Defining Food-Grade rPET Chips

Different regions have developed their own systems to ensure food-contact safety.

In India, the Food Safety and Standards Authority of India (FSSAI) governs materials that come into direct contact with food. The country’s circular economy roadmap is now considering pathways for certified recycling lines to produce food-graderPET that complies with strict decontamination and traceability standards.

In Europe, the European Food Safety Authority (EFSA) approves recycling processes after evaluating scientific data on contamination removal. Only EFSA-authorised recyclers can produce rPET for food packaging.

In the United States, the FDA grants No Objection Letters (NOLs) to recycling technologies that meet its safety benchmarks. These authorisations confirm that the rPET resin produced is suitable for direct contact with food.

All three systems focus on one principle: rPET must be processed under controlled, tested, and traceable conditions before being used in food containers made from rPET chips. At JB Ecotex Ltd., our rPET chips are both FSSAI and FDA-certified.

From Bottles to Containers: The Journey of rPET Chips

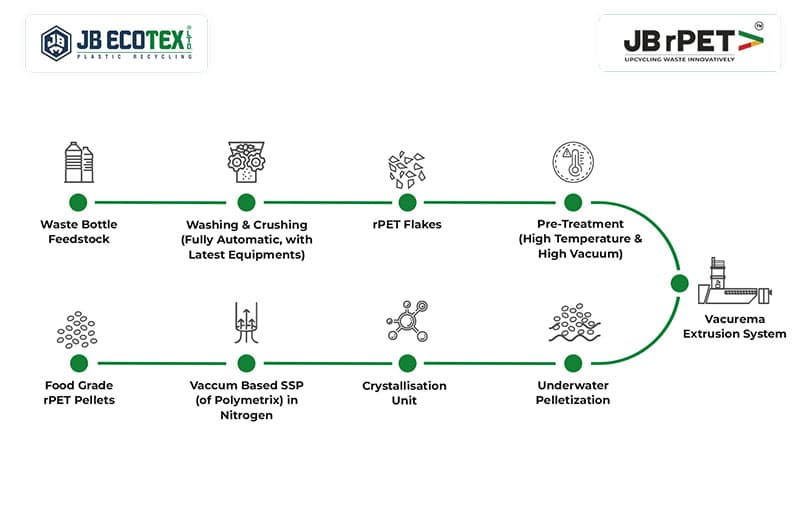

Every safe food container made from rPET begins with disciplined collection. Bottles are sorted, washed, and shredded into clean PET flakes. These flakes are then melted, filtered, and pelletized into rPET chips, forming the base material for packaging converters.

Converters transform these chips into punnets, trays, and multilayer sheets using thermoforming or injection moulding. The result is a product that maintains PET’s clarity and strength while significantly reducing the environmental impact compared to virgin resin.

Each stage of the process depends on traceability. JB Ecotex operates with a dedicated collection and monitoring network that tracks the source and quality of its feedstock. This transparency supports both EPR compliance and long-term trust in the recycled supply chain

Testing and Certification of Food-Grade rPET

Before being used for packaging, rPET chips undergo laboratory testing to verify their safety. Migration and contamination analyses simulate real food-contact conditions such as time, temperature, and exposure to different food types. Results must demonstrate that no harmful transfer occurs.

These tests are reviewed by national or international authorities, depending on the region of sale. Alongside this, recyclers document every step of their process, from input quality to extrusion parameters, creating a transparent record that ensures accountability and regulatory confidence.

Environmental Impact and the Case for rPET Chips

The environmental advantage of rPET chips food containers lies in how much energy and raw material they save. Producing PET resin from virgin feedstock requires new petrochemical resources and large amounts of energy. Recycling existing PET consumes significantly less energy and produces far fewer greenhouse gas emissions.

Studies show that rPET production can reduce carbon emissions by up to 60 percent compared to virgin PET manufacturing. Beyond carbon, rPET extends material life. Each recycled bottle becomes raw material for another product, keeping plastic in use instead of sending it to landfills. This simple shift is at the core of circular packaging design.

India’s Evolving Role in Food-Grade rPET

India’s PET recycling industry is well established, but most of its output still serves textile and non-food sectors. The demand for food-grade material is now increasing, driven by new packaging mandates and brand commitments.

With EPR implementation and growing awareness about resource efficiency, investments in super-clean recycling technologies are accelerating. These developments will enable recyclers to produce certified rPET that meets international safety standards for food-contact applications.

JB Ecotex’s continuous improvement in process technology and zero-liquid-discharge operations aligns with this national movement. As regulations mature, such facilities will play an essential role in supporting India’s transition to responsible packaging systems built on rPET.

Balancing Safety, Quality, and Circular Design

Consumer confidence depends on more than a recycling logo. It relies on evidence. Verified recycling data, clean manufacturing environments, and strong quality assurance are all part of that proof.

Modern recyclers now maintain digital documentation for every batch of rPET chips, tracking bottle origins and process conditions. Packaging converters can use this data to show compliance with both food safety and EPR obligations.

At the design stage, brands are reducing unnecessary pigments and additives, making containers easier to recycle. The integration of rPET chips into this cycle ensures packaging retains its clarity and safety while moving closer to full circularity.

The Future of rPET Chips in Food Packaging

The next chapter of food packaging is already being written with rPET. Global demand for recycled resin is rising quickly, and technology continues to evolve. In India, the shift from conventional recycling to verified food-grade production is one of the most important industrial transitions underway.

Public policy, private innovation, and consumer awareness are now aligned. As infrastructure for traceable collection expands and more recycling processes gain official validation, certified rPETchips food containers will become a common sight across supermarket shelves and export markets.

This transformation is not just technical but cultural. It signals that recycled materials can be clean, compliant, and desirable. Food packaging made from rPET is no longer a compromise. It is a sign of responsibility done right.

Closing Thoughts on rPET in Food Packaging

Every rPET chip tells a story about resource recovery, scientific progress, and collective intent. It represents how the packaging industry is learning to close loops without losing trust or performance.

Food packaging will continue to evolve, but its direction is clear. The future belongs to materials that can prove both safety and sustainability. rPET chips make that balance possible.

For manufacturers, converters, and brands, adopting rPET is not only a compliance measure. It is a statement that innovation can protect what matters: the product inside and the planet outside.