What Recycled PET Flakes Buyers Look for in 2025: Quality, Certifications & Global Trends

The journey from bottle to brilliance

Somewhere in a bustling city, a cold drink was finished, and the bottle placed in a bin. A few weeks later, that very bottle might have found itself in the threads of a sports jersey or molded into a sturdy tray holding fresh produce. Across continents, this quiet but powerful cycle continues every day.

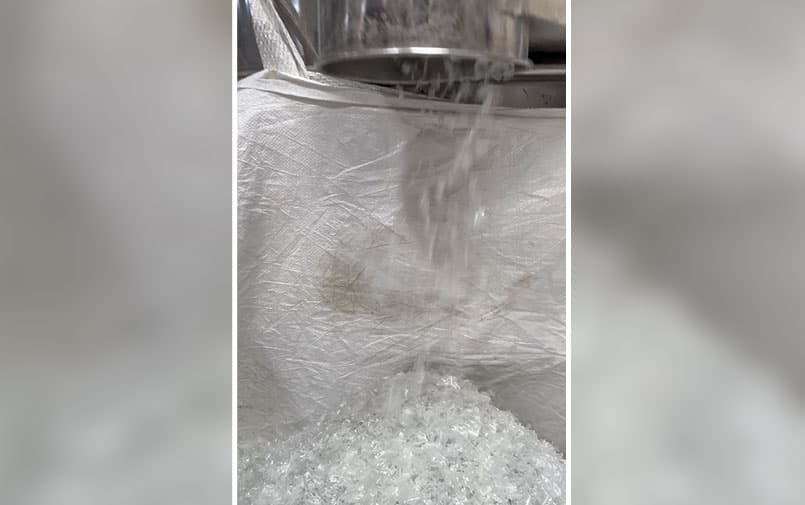

This transformation begins when the bottle becomes a flake. Shredded, cleaned, and sorted, recycled PET bottle flakes form the foundation for some of the most versatile products in the market today. These flakes hold potential. They are processed with care, shaped with intention, and selected by industries that rely on precision and performance.

Recycled PET flakes buyers understand the value within these chips. Each order is carefully chosen. Every specification is reviewed. The buyer is not just sourcing plastic; they are sourcing responsibility, consistency, and trust.

As 2025 unfolds, the demand for high-performing, transparent, and traceable PET flakes continues to rise. Whether used in packaging, textiles, or industrial strapping, these flakes now carry a larger role in global manufacturing.

What are recycled PET flakes?

Recycled PET flakes are cleaned and processed chips made from polyethylene terephthalate (PET) bottles. These flakes are not melted or pelletized. They serve as an intermediate material for converting used plastic into functional products across a variety of industries.

Recycled PET bottle flakes are used in:

- Transparent trays and clamshell packaging

- rPET flakes for FSSAI and FDA-certified rPET resins

- PET straps for transport

- Yarn and fiber for textiles

- Sheet extrusion for thermoforming

- Injection molding via PET lumps buyers

Their use spans the packaging, textile, construction and automotive industries.

Who’s buying recycled PET flakes in 2025?

PET flakes buyers now include a wide range of professionals. Procurement managers from large FMCG companies, sustainability teams from packaging converters, textile sourcing heads, and even start-up founders building new circular product lines are all part of the demand ecosystem.

PET bottle flakes purchasers working in rigid and flexible packaging, recycled flakes for textile sourcing leads, and PET lumps buyers in the injection molding segment each have specific performance and documentation expectations. Understanding these personas allows suppliers to create more tailored and transparent offerings.

What recycled PET flakes buyers prioritize in 2025

Reliable and consistent flake quality

Buyers in 2025 are aligned in their expectations. They review every lot for clarity, stability, and cleanliness.

Important characteristics include:

- Visual clarity with a consistent shade

- Low moisture for smoother extrusion

- Stable intrinsic viscosity (IV)

- Clean surface finish, as seen in hot-washed PET flakes

- Minimal dust or fines

- Controlled particle size distribution

Flakes that perform well in trials are often chosen for longer-term supply. Recycled flakes for textile require brightness and flow, while rPET flakes for sheet extrusion benefit from low acetaldehyde content.

Certifications for safety and market readiness

Certification provides assurance. Recycled PET flakes buyers often begin their sourcing process by reviewing documentation.

The most requested certifications include:

- FDA approved rPET flakes for food-grade packaging

- EFSA dossiers for European applications

- BIS certification for Indian markets

- GRS and RCS for textile traceability

These documents often accompany the material or are made available digitally. Buyers also request compliance reports to meet their own sustainability disclosures.

Preference for post-consumer sources

Material origin plays an important role in purchase decisions. Flakes made from post-consumer PET flakes are aligned with circular economy goals. These flakes represent bottles collected from homes, offices, and public spaces.

Buyers prefer this origin because:

- It supports extended producer responsibility

- It is recognized by brand partners

- It demonstrates real-world recycling impact

Suppliers often share bale traceability and collection data to support buyer expectations.

Price, performance, and long-term value

Cost continues to matter. However, recycled PET flakes buyers are finding more value in reliable performance and steady supply. A slightly more consistent flake can lead to fewer downtimes, less scrap, and better product quality.

For buyers producing high-visibility packaging or textile products, maintaining color consistency or IV stability often results in fewer rejections and better efficiency. Flakes that arrive on time with updated documentation and clean processing records provide peace of mind, especially for those supplying large retail or export contracts.

Matching flakes to end applications

The best flakes are those selected for a specific use. PET flakes buyers review technical requirements and run tests to match grade with product.

Examples include:

- Textile yarn manufacturers choose flakes with higher IV, brightness, and no color variation

- Sheet extrusion companies require flakes with narrow IV range and low haze

- PET lumps buyers request crystallized and densified flakes for injection applications

- Strap manufacturers rely on high-purity PET flakes with stable tensile properties

Each use case has a flake specification that suits it best.

How suppliers can meet buyer expectations

Suppliers that align with evolving industry needs often stand out in competitive markets. Recycled PET flake suppliers can improve buyer experience by:

- Keeping certifications updated and accessible

- Maintaining batch-wise quality logs and IV reports

- Sharing digital traceability and collection source records

- Responding to technical data requests with transparency

- Customizing flakes for sheet, textile, strap, or lump applications

These small adjustments create smoother onboarding, quicker approvals, and stronger relationships with recycled PET flakes buyers.

From bottle to flake: The production flow

Understanding the journey of a bottle helps buyers appreciate each quality checkpoint. A standard PET flake production line includes:

- Bottle collection (often post-consumer)

- Sorting (automated and manual)

- Label and cap removal

- Shredding

- Hot-washing PET flakes with friction

- Float-sink separation

- Drying

- Optical sorting and packaging

- Testing for IV, moisture, contamination, and color

Each stage is key to creating flakes suitable for food-grade packaging, textile spinning, or industrial sheet applications.

Digital traceability and real-time insights

Buyers are adopting smarter tools for quality control and logistics. Sensors, digital dashboards, and blockchain records now support the movement of each shipment.

Flakes often come with:

- Bale traceability

- COA documents linked by QR codes

- IoT-monitored container conditions

- Moisture and IV reports sent ahead of delivery

These systems help buyers make informed decisions, ensure consistency, and prepare production schedules without delay.

What buyers appreciate solving together with suppliers

Collaboration builds results.

Adjusting moisture levels, customizing particle sizes, or tweaking IV to suit a specific extruder often leads to better product outcomes. Suppliers that create channels for ongoing communication are better positioned to respond to new applications, markets, and regional preferences.

Global trends shaping the rPET flakes market

Across different countries, the momentum for recycled materials continues to grow.

- In Europe, minimum recycled content laws are leading to increased demand for FDA approved rPET flakes and EFSA-compliant material.

- In North America, collection programs are adding more material to the system, creating greater availability of post-consumer flakes.

- In Asia, infrastructure investments and government policies are strengthening the position of the India rPET flakes exporter, allowing manufacturers to deliver certified material at scale.

Digitalisation is also helping buyers place orders, request documents, and track samples through centralized platforms. This supports quicker decisions and stronger supplier relationships.

Looking ahead: How buyers can stay ready in 2025

Buyers who evaluate their needs early, align with suppliers offering transparency, and build material-specific partnerships will be ready for emerging demand.

Trial runs with rPET flakes for sheet extrusion, targeted sourcing of recycled flakes for textile, and closer engagement with certified clear PET flakes suppliers can provide a competitive edge. Buyers can also benefit from proactive sampling, scheduled quality audits, and access to digital records that simplify compliance.

What buyers value most

Buyers in 2025 are thoughtful and process-driven. They evaluate each shipment with care, choose based on clear data, and align material choice with product purpose.

They prioritize:

- Quality that fits their application

- Certifications like FDA approved rPET flakes and BIS

- Post-consumer sourcing

- Real-time visibility and traceability

- Reliable support from experienced India rPET flakes exporters

The value of recycled PET flakes lies in performance, precision, and preparation. Buyers who focus on these elements strengthen their supply chains and build resilience in an evolving materials market.

Looking for consistent, certified and application-ready PET flakes?

At JB Ecotex , we process high-quality recycled PET bottle flakes with a focus on clarity, compliance and customisation. Whether you need hot washed PET flakes, rPET flakes for sheet extrusion, or flakes suited for textile and strapping, our team ensures reliable quality with every lot.

Connect with us today to explore product-specific samples, technical documentation and long-term supply support built for your process.