Mechanical Recycling: The Backbone of rPET Flakes, PET Plastic Flakes and Recycled PET Granules Production

How Mechanical Recycling Continues to Shape Global Recycling Systems

The global shift toward circular materials has placed the spotlight on recycled PET. Industries that depend on packaging, textiles, and consumer goods now require steady access to high-quality recycled materials. Regulations in several regions have created new expectations for recycled content. Brands that previously treated sustainability as a long-term goal are shifting to immediate action. These pressures are creating a structured environment where supply chains must be strong, predictable, and safe.

At the core of this change lies mechanical recycling of plastic. This process has become the most dependable pathway for converting post-consumer PET bottles into materials such as rPET flakes, food-grade resins, PET plastic flakes, and recycled PET granules. Countries with established collection systems benefit from their maturity. Countries with developing collection networks rely on it because it offers clarity and stability. JB Ecotex has played a role in reinforcing this stability with advanced mechanical processes that support consistent plastic reprocess granules performance and rPET material supply.

Mechanical recycling functions on a simple principle. PET bottles are collected, cleaned, and transformed through physical processes that preserve the polymer chain. This is different from chemical recycling, which breaks down PET into monomers before rebuilding it. Both pathways have value. The focus of this blog is the continued relevance of mechanical recycling and its role as the foundation for materials such as rPET flake, PET plastic flakes, recycled PET granules, and several other recycled forms that support packaging and industrial applications.

The presence of mechanical recycling shapes global recycling systems for bottle to bottle recycling because it balances quality, efficiency, and cost. The process evolves each year with better sorting technology, advanced washing lines, and improvements in solid-state polymerization that support food-grade applications. These refinements help producers meet the needs of converters who expect uniformity and reliability. Converters rely on stable melt flow behaviour, viscosity ranges, and decontamination performance. Mechanical recycling delivers these outcomes when the feedstock and process conditions are maintained at high standards

Why Mechanical Recycling Remains the Central Pathway for rPET Flakes, PET Plastic Flakes and Recycled PET Granules

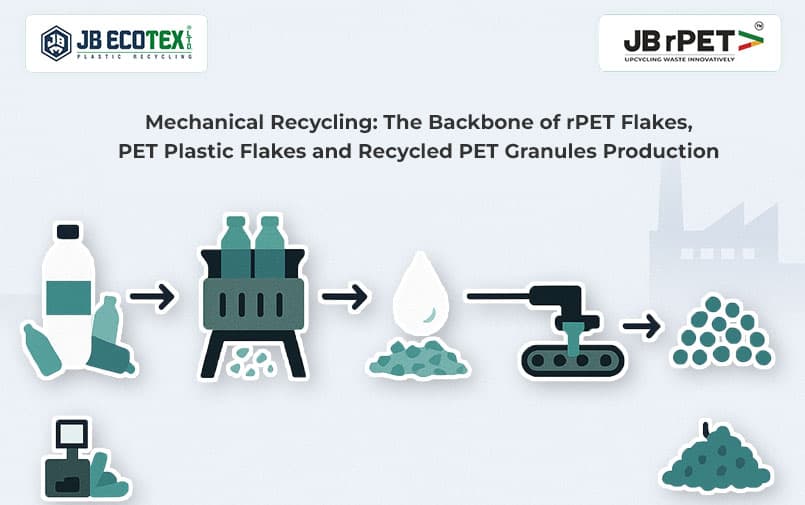

Recycling systems across the world rely on mechanical recycling because it supports high volumes efficiently. It converts bottles to usable material through a predictable sequence of steps. This sequence includes sorting, washing, label removal, shredding, hot wash, drying, and further refinement processes that prepare flakes for downstream applications. The pathway produces rPET flakes and PET plastic flakes that become the base for recycled resin, fibre, sheet, and several forms of packaging.

1. Strong compatibility with bottle-grade applications

Bottle-to-bottle production requires tight controls. Decontamination, intrinsic viscosity stability, and melt flow behaviour must meet strict standards. Mechanical recycling has demonstrated that it can meet these expectations when supported by advanced lines and strong quality systems. Plants like JB Ecotex that use sophisticated washing, drying, and solid-state processes supply material that fits the requirements for several packaging applications. This helps reinforce long-term confidence in the recycled PET supply and plastic reprocess granules.

2. High scalability and low environmental load

The steps involved in mechanical recycling depend on physical cleaning and transformation rather than chemical reactions. This reduces energy consumption for many applications. The ability to scale operations without major increases in complexity supports industries that require high volumes. Regions with large populations depend heavily on this characteristic because it allows quick responses to demand growth.

3. Predictable output for multiple industrial segments

Converters in packaging and textiles require different grades. rPET flake quality determines how easily downstream units can adapt it into sheet, filament, or food-grade material. PET plastic flakes produced through mechanical systems offer the consistency necessary for these varied uses. They maintain polymer integrity to a degree that supports mechanical strength and processing performance. The same is true for recycled PET granules, which rely on the stability of the underlying flake.

4. Strong alignment with established supply chains

Collection networks, sorting units, and recyclers have built their systems around mechanical processes. This integration creates a functional ecosystem where each participant understands the requirements. The feedstock moves through familiar channels, and the output enters supply chains with minimal disruption. This stability makes mechanical recycling a dependable foundation for circular PET and rPET material goals.

5. Lower complexity for converters

Converters using recycled resins benefit from feedstock that performs predictably. Mechanical recycling supplies this predictability because the polymer chain remains intact through much of the process. The result is easier processing during extrusion, injection, or thermoforming. Converters can tune their systems for consistent performance without adjusting to large property variations.

Mechanical recycling supports the daily operations of large parts of the recycled PET industry. Its reliability and scalability make it a natural fit for rPET flake production and the creation of PET plastic flakes and recycled PET granules. These materials support several downstream pathways, including those that rely on raw materials for PET bottle production.

How Mechanical Recycling Enables a Stable Flow of rPET Flakes, Recycled PET Granules and PET Plastic Flakes into the Market

A successful circular PET system depends on uninterrupted material flow from collection to conversion. Mechanical recycling supports this requirement by creating structured processes that reduce variability. The system accepts clear PET bottles, removes contaminants, and transforms them into valuable materials. Countries with large consumption volumes depend heavily on this predictable flow.

1. High-quality rPET flake production

rPET flake acts as a central material in the recycling value chain. It serves as feedstock for producing food-grade resin, fibre, nonwoven materials, and thermoformed packaging. The ability of mechanical recycling of plastic to maintain stable quality helps all these industries function smoothly. rPET flake also supports sheet and film applications where clarity and mechanical strength matter.

2. PET plastic flakes for packaging and sheet

PET plastic flakes undergo further refinement to serve packaging, sheet extrusion, and thermoforming. Their clarity, stability, and cleanliness influence how well they process in converters. Mechanical recycling gives producers the opportunity to fine-tune the cleaning and decontamination steps to obtain flakes that satisfy multiple performance requirements. These flakes are used for consumer packaging, industrial packaging, and protective films.

3. Recycled PET granules for diverse applications

Recycled PET granules offer a uniform input for converters who need pellet form for consistent feeding and performance. These plastic reprocess granules originate from clean PET plastic flakes. Mechanical recycling ensures that the physical transformation from flake to pellet maintains viscosity and structural qualities. This also supports filament spinning, injection moulding, and sheet production. Industries that make textiles, packaging, and industrial components rely on the stability of recycled PET granules.

4. Supporting raw materials for PET bottle production

The global demand for raw materials for PET bottle manufacturing continues to rise. As more countries transition to recycled content, mechanical recycling becomes an important source of material. Clean rPET flake and pelletised forms support producers who create preforms and bottles. The predictable nature of mechanical recycling helps these producers maintain consistent product performance.

5. Building long-term supply confidence

Converters must plan production months ahead. Brand owners plan packaging portfolios years ahead. Mechanical recycling provides the confidence needed for these timelines. Its presence across many countries and its ability to operate continuously allow brands to commit to recycled content targets with reduced uncertainty.

The stability of mechanical recycling strengthens the global supply chain of rPET flakes, PET plastic flakes, and recycled PET granules. This stability allows industries to integrate recycled materials such as plastic reprocess granules into long-term application strategies.

How the Process Works and Why It Supports

Efficiency Mechanical recycling operates through a structured set of steps. Each step contributes to the final quality of rPET flake and related materials. These steps can include bale breaking, sorting, hot and cold washing, mechanical cleaning, drying, colour separation, and refinement through advanced systems. Technology has improved significantly. This includes optical sorters with artificial intelligence, improved friction washers, and enhanced thermal systems that help remove contaminants.

Plants like JB Ecotex use a combination of efficient washing, controlled heat application, and solid-state treatment to achieve food-grade performance for specific applications. These processes allow the material to reach levels of safety and quality required for packaging. The stability of the mechanical pathway makes it attractive, especially when food-grade resins need consistency.

Why efficiency matters

A circular PET system must scale to serve global needs. Energy use, water use, and process time must align with sustainability goals. Mechanical recycling of plastic supports this alignment because its main steps rely on cleaning and remelting. Even with rising demand, the ability to maintain efficiency helps support sustainable production at industrial levels.

Mechanical and Chemical Recycling Work Together for Future Stability

While mechanical recycling remains the central pillar of the recycled PET industry, the presence of chemical pathways is important for long-term resilience. JBrPET, the chemical recycling subsidiary of JB Ecotex, works on converting PET that would not easily move through mechanical lines. This can include coloured PET, certain contaminated packaging formats, and materials with limited sorting potential.

Mechanical systems manage clean bottles and create materials that support immediate demand. Chemical systems capture value from challenging feedstock and return it to the loop. The coexistence of both technologies ensures greater material recovery. This combination increases the total availability of recycled content and rPET material and helps the global market maintain supply even when waste streams become more varied.

Why Mechanical Recycling Will Continue to Lead the Production of rPET Flakes, PET Plastic Flakes and Recycled PET Granules

A future built on circular packaging depends on systems that can operate consistently at scale. Mechanical recycling already has the infrastructure, industry acceptance, quality frameworks, and energy advantages needed to remain the main pathway.

1. Established global presence

Countries with strong collection networks have built their recycling capacity around mechanical systems. This infrastructure allows immediate scaling and rapid adjustment to demand changes in rPET material.

2. Reliable source of premium materials

High-quality rPET flake, PET plastic flakes, and recycled PET granules are essential for converters. Mechanical recycling of plastic meets this requirement because the polymer is not broken down chemically. The integrity of the chain supports performance in applications that require strength and clarity.

3. Supporting regulatory alignment

Governments are setting recycled content mandates. Mechanical recycling provides consistent volumes that help meet these expectations. Its ability to deliver safe material supports packaging designed for food, beverages, and personal care.

4. Market trust

Converters trust materials that behave predictably. mechanical recycling provides this trust. Its outputs have known performance characteristics, making it easier for downstream users to integrate recycled content into current systems.

5. Resilience during changes in demand

Even when waste composition changes, mechanical recycling remains stable for the clear bottle stream. The clarity of this feedstock allows mechanical processes to function without major disruptions. This stability supports long-term rPET material industry goals.

The Future Ahead for Global PET Recycling

The future of recycled PET depends on strong leadership in mechanical recycling, supported by growth in chemical pathways. Countries with rising waste streams need multiple solutions. Some will use advanced mechanical processes to supply rPET flake and pelletised forms. Others will use chemical recycling to complement mechanical pathways. The combination ensures that more material is captured and returned to the loop.

JB Ecotex continues to play a role in strengthening the mechanical recycling landscape with precise processes that support safe, stable, and technically reliable outcomes. Its subsidiary JBrPET expands the future potential of recycling systems by exploring pathways for complex PET waste. Together, they support a balanced approach that aligns with evolving global requirements.

Mechanical recycling of plastic remains the backbone of the industry. It produces rPET flakes, recycled PET granules, and PET plastic flakes that support a range of industries. It helps convert raw materials for PET bottle production and aligns with global goals for circularity. As the world moves toward more sustainable packaging, mechanical systems will continue to be central. They offer stability at a time when the demand for recycled content is rising across markets.

The road ahead will require continued collaboration, technology upgrades, and responsible resource management. Mechanical recycling will remain at the heart of recycled PET production. It will continue to be a trusted pathway that meets the needs of converters, brand owners, and global supply chains. The strength of mechanical systems supports the industry as it moves toward a more circular and resource-efficient future.