Inside the Mechanical Recycling Process of PET: Step-by-Step Guide to Sustainable Plastic Recovery

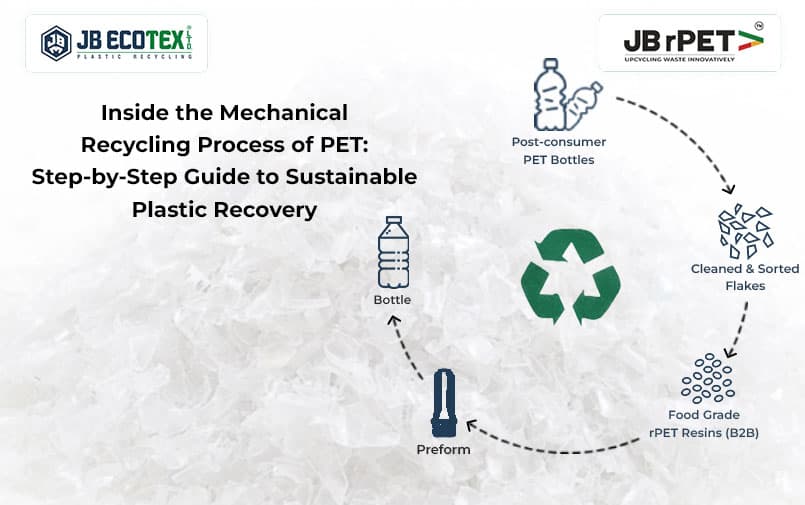

The world is full of plastic, but not every plastic story ends the same way. Some bottles reach a landfill. Others begin again as new packaging, food containers, or fibers. The second story begins with the mechanical recycling process of PET, the system that turns discarded bottles into food-grade resins ready for another life in the circular economy.

This is how waste becomes value.

The Foundation of a Circular Future

PET (Polyethylene Terephthalate) has become the backbone of the global packaging industry because of its strength, clarity, and recyclability. Unlike many polymers, PET can be collected, cleaned, and reprocessed multiple times without losing performance when handled through controlled systems.

Across the world, the PET recycling process has moved from an environmental initiative to a mainstream manufacturing strategy. More packaging converters now prefer mechanically recycled PET resins (B2B) that meet food-safety standards and support sustainability targets.

Before exploring the process itself, it helps to understand the different types of PET recycling shaping this transformation.

Understanding Different Types of PET Recycling

PET recycling takes several routes, depending on the condition of the waste and the end-use requirements.

Mechanical Recycling

This is the most widely used approach. It relies on physical transformation: washing, melting, filtering, and pelletizing. The polymer structure remains intact. JB Ecotex follows this method through advanced Erema Vacunite technology, which converts cleaned PET flakes into food-grade rPET resins for packaging applications.

Chemical Recycling

Chemical recycling focuses on depolymerization of PET, breaking it back into its building blocks. These monomers can then be repolymerized into new PET resins. Through JBrPET, our specialized subsidiary, the JB Group also manufactures CrPET (chemically recycled PET) using advanced depolymerization technology. CrPET complements our mechanical portfolio and makes circularity possible for complex or colored waste that cannot be processed mechanically.

Hybrid Recycling

Emerging hybrid systems combine both methods, offering flexibility for mixed or hard-to-recycle waste streams.

Really, there is no chemical versus mechanical recycling. Each path works toward the same goal: keeping PET in circulation and reducing dependency on virgin raw materials.

Inside the Mechanical Recycling Process of PET: Step-by-Step Transformation

Let’s take a closer look at the process that enables the extended lifecycle of a rPET bottle in detail:

1. Waste Bottle Feedstock

Everything begins with collection. Post-consumer PET bottles are gathered through collection networks and plastic bottle collection machines. Sorting systems separate PET from other polymers, ensuring that only clear, clean bottles continue forward.

2. Washing and Crushing

The sorted bottles enter the washing line, where dirt, labels, and adhesives are removed using hot water and detergents. The bottles are then shredded into small flakes. These flakes form the starting point for mechanical recycling of PET. Clean flakes are critical, as impurities can affect the clarity and performance of the final resin.

3. rPET Flakes: The Building Blocks

Flakes are further sorted for color and purity. Clear flakes are reserved for food-grade applications. When flake quality meets defined purity standards, the resulting resin can comply with global food-contact regulations such as FSSAI and FDA compliance.

4. Pre-Treatment

Before extrusion, the flakes are dried under high temperature and vacuum to remove moisture and volatile residues. Proper drying prevents degradation during melting and ensures consistent intrinsic viscosity in the final resin.

5. Vacurema Extrusion System

This is the heart of the mechanical recycling process of PET.

JB Ecotex uses the Erema Vacunite recycled PET technology, a globally trusted system that combines vacuum decontamination, melt filtration, and solid-state post-treatment in one continuous line. Under vacuum, flakes melt and contaminants are removed without chemical agents. The result is a homogenous, food-safe polymer melt that becomes the foundation for rPET pellets.

6. Underwater Pelletization

The molten PET passes through an underwater pelletizer, where it is cut into uniform pellets that cool instantly in water. Each pellet represents recovered material ready for reuse across packaging lines.

7. Crystallisation

Pellets are crystallized under controlled heat to stabilize molecular structure and prevent sticking during further processing. This step maintains the resin’s mechanical strength and thermal stability.

8. Solid-State Polymerization (SSP) in Nitrogen

Crystallized pellets undergo vacuum-based SSP in a nitrogen atmosphere using Polymetrix technology. Here, molecular chains are rebuilt to restore intrinsic viscosity comparable to virgin PET. The inert environment prevents oxidation and discoloration.

The result is food-grade rPET pellets, stable, transparent, and compliant with food-contact standards.

Quality Control in the Mechanical Recycling Process of PET

In any mechanical recycling process of PET, quality is proven through testing, not assumed. Before pellets reach converters, laboratories typically evaluate key parameters that ensure both performance and safety.

- Intrinsic Viscosity (IV): Measures molecular weight and processing stability for preforms and films.

- Moisture and Acetaldehyde Levels: Critical for maintaining taste and clarity in food and beverage packaging.

- Color and Haze Values: Ensure consistent transparency for packaging applications.

- VOC and Heavy Metal Screening: Detects contaminants and aligns with international food-contact safety standards.

These checks confirm that rPET behaves predictably on blow molding, sheet, and thermoforming lines, and that it remains safe for direct food contact. Across the global industry, these tests form the backbone of validation for mechanically recycled PET resins or B2B resins for the future.

Across the global industry, these parameters define safe, reliable rPET production. At JB Ecotex, we follow the same principles with advanced technology and certified systems in our PET recycling process.

JB Ecotex MrPET: What We Certify and How We Prove It

At JB Ecotex, MrPET resins are produced through this same step-by-step mechanical recycling process of PET, featuring Vacurema extrusion, underwater pelletization, crystallisation, and SSP. Our assurance framework is supported by documented quality systems and recognized certifications:

Our Certifications

- FSSAI for food-contact safety

- FDA Compliance for applicable food-contact requirements

- Global Recycled Standard (GRS) for recycled content traceability and chain of custody

Our Quality Screenings

- Comprehensive VOC Screening to detect volatile compounds

- Heavy Metal Screening aligned with global safety protocols

- Routine QC Metrics, including IV, moisture, acetaldehyde, colour, and haze, verified with batchwise Certificates of Analysis

Each batch of FSSAI-compliant food-grade rPET is traceable and accompanied by detailed test documentation. For converters requiring consistent, compliant, and circular feedstock, MrPET resins deliver verified performance backed by transparent data.

Applications and Benefits of Mechanically Recycled PET Resins

The output of the mechanical recycling process of PET has broad industrial value.

- Food and Beverage Packaging: Bottles, jars, and trays for water, juices, and edible oils use rPET that meets FSSAI and FDA compliance.

- Personal Care and Household Products: Containers for detergents, cosmetics, and cleaners benefit from strong, transparent resins made from recycled sources.

- Industrial and Textile Uses: Non-food flakes can be converted into fibers, straps, and sheets, ensuring complete utilization of collected PET.

- Environmental and Economic Benefits: Using FSSAI-compliant rPET granules lowers carbon emissions, reduces virgin resin dependence, and supports Extended Producer Responsibility (EPR) compliance.

For packaging manufacturers, bottle-to-bottle recycling provides a secure, compliant raw material stream aligned with future global mandates.

Understanding the Process of Recycling Plastic Bottles

The process of recycling plastic bottles usually follows two routes: Mechanical recycling, used by JB Ecotex, focuses on physical reprocessing to create rPET.

Chemicalrecycling, developed by JBrPET, applies controlled depolymerization to produce CrPET, which matches the performance of mechanically recycled resins and expands recyclability to more complex waste.

Together, these technologies form a complete recycling ecosystem within the JB Group.

Why Manufacturers Prefer the Mechanical Recycling of PET

For packaging converters and resin buyers, mechanical recycling of PET offers a balance of reliability, scalability, and environmental performance that few other recycling routes can match. The process preserves polymer strength and clarity while staying economically feasible for large-scale operations.

1. Proven Industrial Scalability

Mechanical recycling systems, like the Erema Vacunite extrusion line, operate continuously with stable throughput. This makes them ideal for high-volume production of mechanically recycled PET resins (B2B) used in bottles, preforms, and films.

2. Stable Resin Properties

Unlike many recycled materials, rPET produced through mechanical processes maintains predictable intrinsic viscosity (IV) and molecular stability, ensuring consistent performance on injection and stretch-blow moulding lines.

3. Energy Efficiency

The mechanical recycling process of PET consumes significantly less energy compared to virgin polymerization or chemical recycling. This lowers carbon footprint and helps manufacturers meet EPR and ESG targets without changing their existing equipment.

4. Cost-Effectiveness and Supply Security

Since the process depends on post-consumer bottles, mechanical recycling provides a reliable raw material supply independent of crude-based feedstocks. Price volatility is lower, offering long-term production stability for packaging companies.

5. Compliance and Traceability

Through technologies like Erema Vacunite, decontamination and process control ensure compliance with FSSAI, FDA, and GRS standards. Every pellet produced is traceable, which supports documentation for audits and sustainability reporting.

6. Circular Economy Alignment

The mechanical route enables closed-loop recycling, where bottles return as bottles. This “bottle-to-bottle” potential supports brand sustainability goals without requiring reformulation or new material approvals.

For manufacturers seeking both performance and responsibility, the mechanical recycling of PET is an advantageous solution that delivers material integrity and circular value simultaneously.

Why rPET Is as Reliable as Virgin PET

Modern recycling technologies ensure that rPET maintains the same clarity, strength, and viscosity as new resin. Systems like Erema Vacunite achieve deep decontamination and controlled polymer restoration, allowing PET mechanical recycling to meet food-contact standards.

Manufacturers prefer rPET because it performs consistently while fulfilling sustainability and EPR requirements.

- Comparable strength and processing stability

- Verified regulatory compliance

- Improved consumer perception for sustainable packaging

- Contribution to circular economy goals

The Bigger Picture: Circularity in Practice

The mechanical recycling of plastic is not just a technology; it’s a coordinated system involving collectors, recyclers, converters, and regulators. When manufacturers choose FSSAI-compliant rPET granules, they support a loop where resources stay active, traceable, and compliant. Each pellet reflects accountability and innovation working together.

FAQs: Mechanical PET Recycling and Food-Grade rPET Explained

1.

What is the mechanical recycling process of PET?

It involves

collecting, washing, and shredding used bottles into flakes, drying and

decontaminating them, melting through an extrusion system such as Erema

Vacunite, and then pelletizing, crystallizing, and polymerizing to form

food-grade rPET pellets.

2.

What is the difference between mechanical and chemical PET recycling?

Mechanical

PET recycling reprocesses plastic through physical means, while chemical

PET recycling breaks it into monomers for repolymerization. Mechanical

recycling is currently more energy-efficient and widely adopted, while chemical

recycling expands the range of recyclable materials.

3.

Is rPET safe for food packaging?

Yes. Systems

like Erema Vacunite recycled PET technology remove impurities and

restore polymer integrity, producing resins approved under FSSAI and FDA

compliance.

4.

Why is the Erema Vacunite system significant?

It integrates

decontamination, melt filtration, and solid-state post-treatment in a closed

system, delivering high-purity mechanically recycled PET resins (B2B)

suitable for food contact.

5.

What is depolymerization of PET?

It is a chemical

process that breaks PET into its original monomers. These can be used to

manufacture CrPET, as produced by JBrPET, enabling recycling of

complex or colored PET.

6.

Can rPET match virgin PET in performance?

Yes. Properly

processed food-grade rPET pellets have similar clarity, viscosity, and

mechanical strength to virgin PET.

7.

What are the main applications of mechanically recycled PET?

They include

beverage bottles, packaging films, household containers, fibers, and industrial

straps.

8.

How does PET recycling reduce environmental impact?

By extending

polymer life, the mechanical recycling process of PET cuts energy use,

reduces virgin resin demand, and minimizes landfill waste.

9.

How does JB Ecotex ensure safety and traceability?

Every step, from

bottle collection to SSP, is monitored under FSSAI and GRS standards and

processed using Erema Vacunite for verifiable quality and traceability.

10.

What is the future of PET recycling?

Advancements in

collection, extrusion, and hybrid technologies will strengthen both MrPET

and CrPET, making circular packaging the global standard.

Conclusion: Engineering the Future of Packaging

The journey from bottle to pellet captures the essence of a true circular economy. The mechanical recycling process of PET proves that sustainability can align with industrial efficiency. Each stage transforms waste into certified raw material ready to re-enter the supply chain.

JB Ecotex leads this transformation through mechanical recycling, while JBrPET extends it with chemical recycling to produce CrPET. Together, they form a complete system that keeps resources in motion and supports a cleaner packaging future.

By choosing FSSAI-compliant rPET resins, manufacturers secure not just a material, but a commitment to long-term circularity.

About JB Ecotex

JB EcotexLtd. is a leader in sustainable polymer solutions, specializing in the mechanical recycling of PET through Erema Vacunite recycled PET technology. As part of the Jay Bharat Group, JB Ecotex works alongside JBrPET, its chemical recycling arm, to deliver both MrPET and CrPET for diverse packaging and industrial applications. Through transparency, compliance, and innovation, we continue to shape the future of circular plastic recovery, one bottle, one resin, one cycle at a time.