A Sustainable Approach with rPET Bottle-to-Bottle Granules in India — 2025 Update

Why Resin Has Become the Center of the Sustainability Debate

We, at JB Ecotex, have been watching this shift long before it became a headline. Long before rPET was trending in reports and long before recycled content became a compulsion in packaging laws, the conversation had already started on the factory floor. Engineers asked us if recycled resin could hold its IV. Buyers asked how far regulators would go in approving it. And brands asked the question no one wanted to ignore: Will consumers trust packaging made from recycled bottles?

Over the years, those questions have only grown louder. What began as curiosity is now industry policy, consumer expectation, and brand strategy. The resin at the center of this shift is rPET bottle-to-bottle granules: chips that carry the same clarity and strength as virgin PET, but with a circular story that goes far beyond the shelf.

This is not a new conversation for us. It is one we’ve been part of for years, and it is reshaping how India’s packaging industry prepares for its future.

PET Bottle Chips: The Material Behind Every Bottle

In India, the term “chips” is used interchangeably for PET pellets, granules, or dana. These bottle chips are what converters melt, mold, and blow into preforms and containers. Traditionally, PET bottle chips have been virgin, produced from PTA and MEG.

The shift now is toward recycled PET chips or rPET bottle-to-bottle granules made by taking used bottles, cleaning them thoroughly, and reprocessing them into food-contact-safe resin. In form they look the same as virgin chips, but in impact they represent a move toward circular packaging.

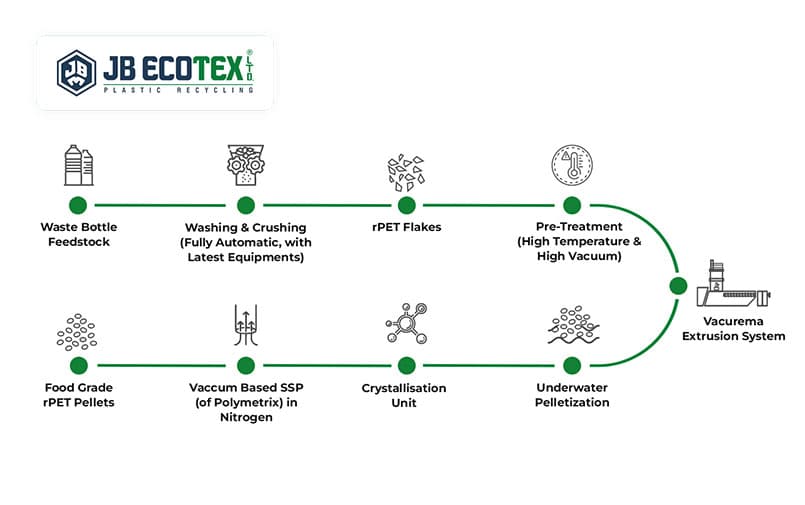

How rPET Bottle-to-Bottle Granules Are Made at JB Ecotex

At JB Ecotex, the process begins with collection. Post-consumer PET bottles are sorted, labels removed, and contaminants screened out. The flakes produced then enter our EREMA VACUNITE line, which combines vacuum extrusion with nitrogen-based solid-state polycondensation (SSP).

This matters for two reasons:

- Decontamination: volatile compounds are removed under vacuum, ensuring no carry-over of odors or residues.

- IV restoration: the SSP step rebuilds the intrinsic viscosity, giving the resin the strength it needs for bottles and jars.

The result is recycled PET bottle chips that meet food-grade standards, indistinguishable in application from virgin chips, but aligned with sustainability commitments.

Compliance Defines Food-Grade Packaging

The rise of rPET in India is closely tied to regulations like Plastic Waste Management (Amendment) Rules, 2022. For any food-contact resin, approvals are non-negotiable.

- FSSAI has opened the door for recycled PET in packaging, provided the process meets its requirements.

- FDA and EFSA frameworks guide global acceptance of recycled PET for export markets.

- GRS certification adds assurance of traceability.

At JB Ecotex, our rPET resin FSSAI compliance and FDA alignment give manufacturers the confidence that they are sourcing material that regulators trust. If you are planning trials, our team can share FSSAI certification details and test summaries for your QA documentation.

Grades of PET Plastic Resin for Different Applications

Not all applications demand the same resin grade. Our rPET bottle-to-bottle granules are produced in three IV ranges, each suitable for a different packaging need:

- 0.76 dL/g → water bottles and lightweight thermoforming sheets.

- 0.80 dL/g → juices and regular beverage bottles, balancing processability and durability.

- 0.84 dL/g → carbonated drinks, jars, and heavier-duty rigid packaging.

This mapping helps converters match resin supply to their product lines with clarity.

Quality Control from Bale to Bag

Between incoming bales and outgoing resin, our lab runs multiple checks to safeguard consistency:

- VOC screening to prevent taste or odor issues.

- Heavy metal testing to align with global standards.

- Multi-stage in-process QC to catch deviations early.

- Dual metal detection at both input and final packing

- SAP-linked barcoding for traceability across every batch.

This system ensures that each bag of rPET bottle-to-bottle granules can be traced, verified, and trusted in production.

Where rPET Chips Are Being Used Today

Converters in India and abroad are now adopting rPET bottle-to-bottle granules across:

- Packaged water and soft drink bottles.

- Juices, dairy-based beverages, and edible oils.

- PET jars for condiments and dry food products.

- rPET resin cosmetic packaging for jars and bottles in personal care.

- Sheets, straps, and films for secondary packaging.

The applications show how recycled PET chips are moving from experimental to mainstream.

Sustainability That Extends Beyond Resin

For manufacturers, sustainability is not just about recycled content. Buyers and brand auditors ask about the entire supply chain. At JB Ecotex, two practices stand out:

- Renewable energy from wind and solar reduces the CO₂ footprint per tonne of resin.

- Zero Liquid Discharge (ZLD) ensures every drop of process water is treated and reused, not wasted.

These choices fold neatly into EPR reporting and brand disclosures. When brands track food packaging environmentally friendly inputs, they look for proof at the resin level. We maintain those records so your audits stay organized.

Where Converters Are Using rPET Today

Applications continue to widen across India.

- Packaged water, CSD, and juices that prefer rPET granules beverage packaging for recycled content goals.

- Jars for dry foods and spreads supplied from IV-appropriate grades.

- Sheets, straps, and films where circular inputs strengthen sustainability files.

- Personal care and beauty where rPET resin cosmetic packaging keeps form factors familiar while lifting recycled content.

Teams building environmentally friendly food packaging programs often start with a single SKU, then extend to families of products as line settings stabilize. This phased method also helps when brands want food packaging environmentally friendly claims backed by resin records.

Sustainability and the Global Landscape

The movement toward rPET bottle-to-bottle granules is not unique to India. Across the world, governments, brand owners, and consumers are accelerating the shift.

- Global brand pledges: Beverage and FMCG giants have publicly committed to using 25–50% recycled PET in bottles by 2025–2030. These targets are already shaping procurement and supplier requirements.

- Regulatory frameworks: The European Union has mandated minimum levels of recycled content in PET bottles, while the US FDA continues to expand its list of approved recycling processes. These policies set benchmarks that Indian exporters must keep pace with.

- Consumer awareness: In markets like Europe and North America, “made with recycled PET” has moved from being a niche claim to a mainstream expectation. This pressure is beginning to influence buyers in Asia as well.

- Trade opportunities: Export-oriented manufacturers in India who align with rPET resin FDA and global sustainability standards find it easier to integrate into global supply chains.

For Indian converters, the message is clear. rPET is not only about local compliance. It is also about preparing to compete in a global packaging ecosystem that is rapidly closing its doors to packaging without recycled content.

Market signals we watch to guide your purchasing

Several indicators help buyers plan the year.

- Recycled content pledges from beverage and personal care brands are accelerating demand.

- The pool of suppliers seeking rPET resin FSSAI documentation is growing, which supports qualification confidence.

- Export asks for rPET resin FDA keep increasing across categories.

- Retailers request shelf-level proof around environmentally friendly food packaging, so resin records matter more each quarter. These signals point toward steady growth in rPET use, especially where rPET fits rPET granules beverage packaging and rPET resin cosmetic packaging pipelines already in place.

A Practical Checklist for Buyers of Food-Grade PET Bottle Chips

When evaluating resin suppliers, procurement teams can ask:

- Does the supplier hold rPET FSSAI approval?

- Is the process FDA aligned?

- What IV grades are available?

- How is traceability documented?

- What sustainability practices can be shared with auditors?

A Quick Procurement Checklist For Resin Buyers

Keep this list handy during supplier evaluations.

- Current rPET resin FSSAI documents and a plain-language tech summary

- Export pathway with rPET resin FDA references where relevant

- QC steps, VOC and heavy-metal screening, and retained-sample policy

- Clear IV options for PET plastic resin and rPET Bottle-to-Bottle Granules with typical uses

- Packing formats, batch barcoding with SAP traceability

- Trial support, first-article templates, and post-trial documentation

- Availability for PET bottle chips if you plan comparative runs

Food-grade rPET with FSSAI compliance, clear IV choices, and tight QC. Send your target SKU and we will share a grade recommendation and a short trial plan.

Your First Month With rPET: A Model Rollout

Week 1. Lock grade and targets. Align the lab list.

Week 2. Run a short lot with records, then review haze, AA, and top-load.

Week 3. Repeat with tuned dryer settings and a larger lot.

Week 4. Publish a short internal note that pairs COAs, settings, and outcomes. Extend to a second SKU.

This rhythm suits beverage teams who want rPET granules beverage packaging volumes in time for seasonal lifts and helps beauty teams moving into rPET resin cosmetic packaging families.

Why The Phrase “Bottle To Bottle” Matters To Your Brand

Bottle-to-bottle shows circularity the customer can understand. The phrase supports visual storytelling on packs and retail shelves. It also connects directly to auditing frameworks that require resin-level proof. When leadership teams choose rPET Bottle-to-Bottle Granules, they receive a resin story that supports claims with clear data from a PET Bottle to Bottle Recycling Plant.

Applications Checklist For Your Team

- Packaged water and CSD

- RTD teas and coffees

- Dairy and flavored milk

- Sauces and condiments

- Spreads and dry foods in jars

- Sheets, straps, and films

- Beauty and personal care under rPET resin cosmetic packaging

This list helps teams decide which lines to move first and where PET plastic resin grades map most naturally.

The Next Five Years Of Resin In India

Expect steady adoption of recycled content across beverages and personal care, stronger requests for proof linked to rPET FSSAI, and wider export contracts that ask for rPET resin FDA pathways. Retailers will continue to prioritize environmentally friendly food packaging on shelf. Converters who secure grade options and trial routines today will enjoy easier growth with larger customers tomorrow.

FAQs, written for quick answers

1) What makes rPET Bottle-to-Bottle Granules suitable for food contact

Decontamination and IV control within super-clean steps create safe, stable resin. Documentation aligned to rPET resin FSSAI and export-oriented rPET resin FDA pathways supports audits and customer requirements.

2) Can I switch a water SKU directly to rPET without long downtime

Teams plan a short, well-documented trial. Set IV, haze, and AA targets, run a small lot, adjust dryer time and throughput, then scale. This reduces changeover stress while protecting productivity.

3) Where do PET bottle chips still make sense in my portfolio

Plants use PET bottle chips for clarity-sensitive SKUs and reference runs. Many then add rPET for recycled content targets. Both can live together while your team builds experience and confidence.

4) Which grades of PET plastic resin should I begin with for beverages

Start with 0.80 dL/g to baseline, then tune toward 0.76 or 0.84 based on torque, haze, and top-load. Keep records, retain samples, and publish a short note for repeatability across shifts.

5) What documents will my auditor ask for during a supplier review

Expect rPET resin FSSAI certificates, test summaries, QC workflow, traceability maps, retained-sample policy, and packing details. Export programs also ask for rPET resin FDA references.

6) How does rPET help with environmentally friendly food packaging goals

Resin from a PET Bottle to Bottle Recycling Plant closes material loops. Teams pair records with grade choices to support environmentally friendly food packaging labels and broader food packaging environmentally friendly initiatives.

Closing Thoughts: Why rPET Bottle-to-Bottle Granules Are the Path Forward

The shift from virgin PET bottle chips to recycled chips is not just technical, it is strategic. It aligns manufacturers with regulation, meets consumer expectations, and builds resilient supply chains.

Every bag of rPET bottle-to-bottle granules represents bottles saved from waste, compliance achieved, and packaging made ready for the future.

Resin decisions shape your packaging, your audits, and your brand promise. rPET Bottle-to-Bottle Granules give manufacturers a path to circularity that pairs science, compliance, and day-to-day practicality. With clear grade maps for PET plastic resin, simple trial routines, a predictable documentation pack, and a supply approach built for auditors, your teams can move with confidence.

Discover how JB Ecotex’s FSSAI-certified rPET resin can support your move to sustainable packaging.