Why Brands Are Switching to Recycled Polyester Staple Fibre for a Greener Future

Brands across the world are spending more time in their raw material rooms. Designers, sourcing heads, plant supervisors, and sustainability teams are inspecting fibers with a different mindset. The conversation around textiles has shifted. A few years ago, recycled fibers were a niche choice for a small group of innovators. Today, they are part of mainstream discussions, especially among manufacturers who need reliability, consistency, and future readiness.

In this changing landscape, Recycled Polyester Staple Fibre is becoming a decisive material choice for companies that want durability, strength, and sustainability without disruption.

The textile supply chain is complex. It moves through spinning, weaving, knitting, dyeing, finishing, and cut to pack stages where every small decision affects product quality. When manufacturers select fiber, they look for predictability. They want a material that behaves well at every step. This is where Recycled Polyester Staple Fibre has been proving its value.

The global shift to responsible materials also aligns with evolving regulations. Many brands want to prepare for the future rather than chase it. They want sourcing strategies that help them meet the expectations of retailers, governments, and conscious consumers. That is one reason for the rise of Recycled Polyester Staple Fibre in both apparel and home furnishing categories.

Let’s read in detail why the industry is moving in this direction and how manufacturers can benefit from the change.

What Is Recycled Polyester Staple Fibre

Manufacturers understand polyester well, but the recycled form often invites curiosity. Recycled Polyester Staple Fibre is a man-made fiber produced from recycled polyester from plastic bottles and other post-consumer PET sources. The idea is simple. PET bottles are collected, sorted, washed, flaked, and processed through a controlled PET bottle fiber manufacturing process that turns them into usable fiber.

The resulting material behaves like polyester fiber used traditionally while contributing to the circular use of resources. When mills talk about sustainable polyester fabric, they often refer to textiles that are made using this fiber.

The process is an engineered response to the rising need for recycled plastic fabric, which is increasingly preferred by brands that want credible sustainable sourcing options.

The Rise of Recycled Material Culture

There is a very real shift happening in fashion and home textiles. Consumers read labels with intention. They ask questions. They want to know how brands are treating their waste, their supply chain partners, and the planet. They want materials that feel responsible.

Popular brands have responded with clear commitments. H&M, Decathlon, Levi’s, Adidas, and many others have introduced collections that feature recycled polyester staple fibre materials. These materials are created using recycled polyester from plastic bottles, which gives PET waste a longer life. This also supports the global effort to reduce the environmental pressure associated with textiles.

The popularity of sustainable polyester fabric is helping companies create strong, long-lasting products with a smaller resource footprint. This shift is no longer driven only by sustainability departments. Purchase teams and mills are also adapting because the market is moving in that direction.

Manufacturers who supply to major global brands feel this demand first. They want reliable sources of recycled psf that have consistent deniers, good strength, and predictable dyeability. They want access to fiber that supports performance textiles while meeting sustainability criteria.

The strong rise in demand has led to rapid developments in production infrastructure. Many companies are upgrading or expanding their recycled polyester staple fiber plant capacities to match global requirements.

Technical Specifications and Variants of RPSF

Manufacturers want clarity before making raw material decisions. Technical predictability matters. Below is a structured, easy-to-reference specification table adapted from JB Ecotex’s RPSF product details.

Technical Specification Table

| Parameter |

Available Options |

| Denier Range |

1.2D and above

(varies by requirement) |

| Cut Length |

Multiple cut lengths

suitable for spinning, non woven, filling, and specialty applications |

| Lustre |

Semi dull, bright,

and other industry standard variants |

| Siliconization |

Siliconized and non

siliconized options |

| Crimp |

Designed for improved

bulk and uniformity |

| Colour |

Primarily white with controlled shade consistency |

| Form |

Solid fiber suitable

for diverse manufacturing needs |

| Source Material |

PET waste collected

through structured supply channels |

Key Features for Manufacturers

- Suitable for spinning ring yarn, OE yarn, and vortex yarn

- Works well in blending with cotton, viscose, wool, and acrylic

- Reliable for non-woven applications like geotextiles, interlinings, and filters

- Stable for fiberfill applications including pillows, quilts, toys, and furnishing

- Designed for process stability in heavy-duty manufacturing lines

These specifications help mills select fiber confidently. They also strengthen the case for using recycled polyester staple fibre when replacing virgin polyester in bulk production.

What Makes Brands Choose Recycled Polyester Staple Fibre

Choosing fiber is not only about sustainability. It is about performance. Manufacturers know that the fabric must withstand weaving stress, knitting speeds, or heavy production cycles. A good fiber makes the entire line run smoother.

Recycled Polyester Staple Fibre has become attractive for sustainable textiles because it offers the following benefits:

- High strength suitable for spinning

- Dimensional stability during weaving

- Improved shape retention in garments

- Durability in home furnishing materials

- A consistent feel that customers appreciate

- Compatibility with blends such as cotton, viscose, and acrylic

Manufacturers want fibers that behave predictably during production. They also want to retain cost efficiency. Recycled materials help achieve this balance while supporting brand commitments.

With global supply chains expanding, sourcing heads want fibers that follow clear quality protocols. A growing number of companies rely on facilities that follow international standards. They also want partners who understand the PET bottle fibermanufacturing process and its technical rigor.

In addition to performance, brands value fibers that come from recycled polyester from plastic bottles because it supports circularity initiatives. It helps them communicate responsible sourcing practices in a credible way.

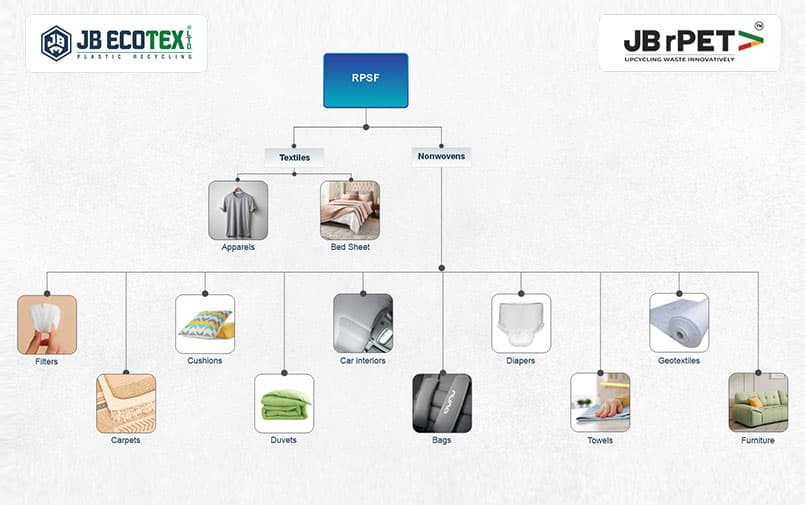

Applications of Recycled Polyester Staple Fibre Across Industries

Different sectors use this fiber differently, but the reliance is equally strong everywhere.

1. Spinning Mills

Recycled fibers blend well and behave reliably during ring spinning, vortex spinning, and OE spinning. Spinners appreciate how the fiber supports good yarn strength and evenness.

2. Knitting Units

Knitted fabrics made with Recycled Polyester Staple Fibre retain elasticity and surface stability. The material works well for athleisure, innerwear, and casual wear.

3. Weaving Units

Weavers use recycled yarns to create shirting fabrics, home textiles, suit materials, and technical textiles. The fiber supports tight constructions without compromising surface appearance.

4. Home Furnishing Manufacturers

Cushions, pillows, quilts, carpets, and sofa fillings depend heavily on recycled psf due to its bulk, resilience, and long-term loft retention.

5. Automotive and Industrial Applications

Many non woven and stuffing products use recycled fibers from trusted recycled fiber manufacturers due to their strength and stability.

6. Non-Woven Industry

Filters, roofing felts, geotextiles, shopping bags, and interlinings benefit from uniform fiber distribution.

How Recycled Polyester Is Replacing Virgin Polyester

Manufacturers across Asia, Europe, and the United States are reconsidering their raw material mix. Many mills once depended heavily on virgin polyester fibres due to their availability. The situation is changing.

Brands see value in increasing their share of regenerated polyester staple fiber in their collections. When purchase teams discuss raw materials now, they explore every possible blend that includes recycled content. They want to tap into global consumer sentiment.

The rise in recycling technology has accelerated this trend. Modern plants follow advanced sorting, cleaning, extrusion, and spinning processes. With every year, the properties of high-grade recycled polyester fabric have improved in performance. This improvement gives confidence to manufacturers who rely on consistent fiber quality.

Large retailers and fashion houses believe that recycled materials signal responsibility. They want textiles to make a clear contribution to their sustainability targets. Their strategy encourages their suppliers to increase orders of recycled psf, especially for:

- Knitted fabrics for activewear

- Woven fabrics for shirting

- Upholstery materials

- Fiberfill for quilts and pillows

- Non woven applications

This movement is gaining momentum, and the textile value chain is shifting with it.

Common Misconceptions About RPSF

Manufacturers often raise thoughtful questions when adopting recycled materials. Addressing them helps everyone make informed decisions. Let’s debunk a few myths about recycled polyester:

Misconception 1: Recycled fibers feel rough

Modern processing has improved surface feel significantly. Mills report good softness levels in blends and finished fabrics.

Misconception 2: Recycled fibers weaken yarn strength

Process advancements help maintain uniformity. Yarn testing often shows balanced results across standard spinning methods.

Misconception 3: Dyeing results vary widely

When fiber quality is consistent, dyeing performance remains predictable. Many mills now rely on recycled yarns for large scale programs.

Misconception 4: Production speed must be reduced

Manufacturers using advanced recycled fibers often maintain their standard machine settings with minimal adjustments.

Consumer Sentiment Is Building Pressure Across the Supply Chain

Consumers rarely see fibers directly, yet they are influencing fiber choices more than before. When shoppers look at hangtags that mention recycled polyester fabric, their perception shifts. They see responsibility in that product. They feel aligned with its purpose.

Consumer research from global institutes shows that many buyers prefer clothes and home textiles made from materials that come from recycled polyester from plastic bottles. They appreciate long-lasting performance, responsible sourcing, and transparency. This sentiment drives retailers to push manufacturers for higher recycled content.

Manufacturers now face a demand pattern where mills supply fabrics, brands demand recycled textiles, and consumers validate that choice. This creates a closed loop that strengthens the role of recycled polyester staple fibre in the market.

How JB Ecotex Supports This Industry Shift in Polyester Material

JB Ecotex has spent years working with PET waste and creating fibers that meet the needs of modern manufacturing. Our work spans the entire journey of PET bottle collection, sorting, cleaning, and conversion into quality recycled polyester staple fibre.

We understand how critical fiber quality is for spinning and fabric production. That is why our production processes follow rigorous standards. Our recycled polyester staple fiber plant supports high-volume production, serving leading manufacturers across multiple sectors.

Our commitment is to create reliable raw materials that integrate into busy production lines without complications.

Our Manufacturing Capabilities

JB Ecotex produces a wide range of deniers and cut lengths suitable for various industries. Our offerings help customers create strong and durable textiles. Manufacturers looking for a consistent supply of regenerated polyester staple fiber with clean and uniform properties depend on our processes.

We also supply fibers for non-woven applications, home furnishings, automotive stuffing, and more. Our position among recycled fiber manufacturers is supported by advanced infrastructure, dedicated teams, and continuous development efforts.

How Our Process Addresses Key Questions from Manufacturers

Manufacturers often have similar questions when they consider using recycled materials. They want clarity on quality, consistency, alignment with future market trends as well as long-term dependability. Here is how our process helps address those questions.

1. Will the fiber behave consistently across batches?

Consistency is a priority. Our plant uses a controlled PET bottle fiber manufacturing process where every stage is monitored. Sorting and cleaning help maintain purity. Melt filtration ensures stable extrusion. These steps help support batch consistency.

2. Can recycled fibers match the feel of virgin polyester?

Many mills have tested blends of Recycled Polyester Staple Fibre with cotton, viscose, or acrylic. The feedback is encouraging. The yarns show good hand feel and performance. Recycled fibers now support a wide range of fabric types used across everyday garments and home furnishings.

3. Will this support brand compliance requirements?

Global brands actively encourage the use of recycled polyester from plastic bottles. Many retailers publish sustainability reports that highlight recycled content. Our customers find confidence in working with a partner that follows clear quality practices and supports their long-term goals.

How to Evaluate a Recycled Polyester Supplier

Manufacturers often want a simple way to assess suppliers. A few points help them make informed decisions.

1. Infrastructure Quality

A strong recycled polyester staple fiber plant uses filtration, controlled extrusion, and reliable quality checks.

2. Waste Traceability

Brands expect transparency in recycled polyester from plastic bottles sourcing.

3. Technical Support

Good partners help mills adjust blends, machine settings, or testing routines.

4. Product Range

Manufacturers prefer suppliers that offer various deniers, lustre levels, cut lengths, and PET fiber options for different applications.

5. Industry Position

Top recycled polyester staple fiber manufacturers in india invest in scalable processes, strong supply chains, and continuous development.

Product Range: RPSF Materials Offered by JB Ecotex

At JB Ecotex, our recycled polyester staple fibre offerings include a broad spectrum of deniers and cut lengths tailored for spinning mills, non woven producers, stuffing industries, and textile manufacturers.

We Offer:

- 1.2D to higher denier variants suitable for diverse applications

- Fibers designed for spinning ring, vortex, or open-end yarn

- Fibers suitable for cushions, pillows, soft toys, quilts, and furnishing

- Specialized variants for non-woven production

- Fibers made from recycled polyester from plastic bottles that follow stringent processing steps

This product range helps us serve multiple sectors at scale. The impact of this one fibre is seen across industries.

Important Points for Teams Working With Recycled Polyester Staple Fibre

- Recycled Polyester Staple Fibre is produced through a controlled recycling process

- The fiber is used in spinning, knitting, weaving, and non-woven industries

- Global brands prefer materials made from recycled polyester from plastic bottles

- Manufacturers use RPSF for apparel, home textiles, furnishings, stuffing, and automotive applications

- JB Ecotex offers multiple deniers, cut lengths, and siliconized variants

- Consumer sentiment strongly supports recycled materials

- Recycled fibers help brands meet sustainability goals with consistent performance

How Manufacturers Can Plan for the Future

The global shift toward sustainable textiles will continue to grow. Regulations may evolve. Retail commitments may deepen. Consumer expectations will rise. Companies that integrate recycled polyester staple fibre early will be better prepared for long-term changes in the industry.

Manufacturers who build resilient sourcing strategies will benefit from greater flexibility. They will also find it easier to meet buyer expectations. Reach out to JB Ecotex to navigate this shift comfortably.

FAQ Section

1. Why are manufacturers shifting to Recycled

Polyester Staple Fibre?

Manufacturers want materials that support stability and

sustainability goals. Recycled fibers help create durable textiles while

supporting responsible sourcing.

2. Does recycled polyester support long-lasting

performance?

Yes. Recycled Polyester Staple Fibre supports

strong yarns and stable fabrics. It can be used across apparel, home

furnishings, and non-woven products.

3. How are plastic bottles turned into textile

fibers?

The PET bottle fiber manufacturing process

includes sorting, washing, flake production, melt extrusion, and fiber cutting.

Each step contributes to creating stable fibers.

4. Is recycled polyester suitable for blending with

natural fibers?

Yes. Blending helps achieve unique fabric properties

while supporting sustainability.

5. Are recycled fibres suitable for high-speed

spinning?

Many mills run recycled blends successfully across

ring, OE, and vortex systems.

6. Are there differences between recycled polyester

fabric and virgin polyester fabric?

There are functional similarities in many applications.

Modern recycling technology supports stable performance.

7. Which industries commonly use recycled psf?

Spinning mills, home furnishing manufacturers,

non-woven units, automotive suppliers, and stuffing industries, basically any

industry that uses polyester fibers in their production.

8. What role do recycled fiber manufacturers play

in supply chain development?

They help create consistent raw materials, improve

waste utilization, and support circularity goals.